Iphampu ye-Shaft eguquguqukayo eguquguqukayo eguquguqukayo iwuhlobo lwephampu oluphakathi nolububanzi obusebenzisa i-blade adge ajuster ukushayela ama-pump blades ukuze ujikeleze, ngaleyo ndlela ushintshe izinguquko zokubekwa kwe-flow kanye nekhanda. Ukudlulisela okuphakathi kwamanzi ahlanzekile amanzi noma indle ekhanyayo ku-0 ~ 50 ℃ (imidiya ekhethekile ifaka amanzi olwandle namanzi aphuzi aphuzi). Isetshenziswa kakhulu emikhakheni yamaphrojekthi wamanzi, ukunisela, ukudonsa kanye namaphrojekthi wokuphambukiswa kwamanzi, futhi isetshenziswa kumaphrojekthi amaningi kazwelonke afana nephrojekthi yokuphambukiswa kwamanzi aseningizimu naseNorth.

Ama-blades we-shaft kanye ne-lixed flow pump ahlanekezelwe ngokwezifiso. Lapho izimo zokusebenza kwephampu ziphambuka ephontweni lokuklama, isilinganiso esiphakathi kwejubane elisezingeni eliphakeme lama-blades angaphakathi nalo liyabhujiswa, okwenza kube nokugeleza kwama-blades, okwenza kube nokugeleza kwamanzi empompini kanye nokulahleka kwamanzi ukuze kwandiswe; Ukude nokude nephuzu lokuklama, kukhula ibanga elikhulu lokufuya kwamanzi kanye nokulahleka kwamanzi. Amaphampu we-axial ne -xubeke ahlanganisiwe anekhanda eliphansi futhi anciphise indawo ephakeme yokusebenza kahle. Ukushintshwa kwekhanda labo lokusebenza kuzodala ukuncipha okukhulu ekusebenzeni kwepompo. Ngakho-ke, amaphampu we-axial ne -xubeke ahlanganisiwe ngokuvamile awakwazi ukusebenzisa ama-threating, ajike nezinye izindlela zokulungiswa ukuze aguqule ukusebenza kwezimo zokusebenza; Ngasikhathi sinye, ngoba izindleko zokulawulwa kwejubane ziphezulu kakhulu, umthetho wejubane oguquguqukayo awuvamile ukusetshenziswa ekusebenzeni kwangempela. Njengoba amaphampu we-axial ne-lihlanganisiwe ahlanganisiwe anomzimba omkhulu we-hub, kulula ukufaka ama-blade nama-blade exhumayo izindlela zodonga ezingalungisa i-angle. Ngakho-ke, ukulungiswa kwesimo okusebenzayo kwamaphampu oku-axial futhi axutshwe amaphampu ahlanganisiwe ajwayele ukwamukela ukuguquguquka okuguquguqukayo, okungenza amaphampu we-axial kanye nokuxutshwa okuxubile asebenze ngaphansi kwezimo zokusebenza ezinhle kakhulu.

Lapho umehluko we-Upstream nokwehla kwamanzi enyuka (okungukuthi, ikhanda likhuphuka), i-angle yokubekwa kwe-blade ilungiswe ngenani elincane. Ngenkathi egcina ukusebenza kahle okuphezulu, izinga lokugeleza kwamanzi lincishiswa ngokufanele ukuvikela imoto ekugcwaliseni ngokweqile; Lapho umehluko we-Upstream nokwehla komfula uncipha (okungukuthi, ikhanda le-Net liyancipha), i-angle yokubekwa kwe-blade iguqulwe ibe yinani elikhudlwana ukuze lilayishe ngokugcwele imoto bese livumela ipompo lamanzi ukupompa amanzi amaningi. Ngamafuphi, ukusetshenziswa kwamaphampu we-shaft namaphampu ahlanganisiwe angashintsha i-engle ye-blade kungenza ukuthi kusebenze esimweni sokusebenza esihle kakhulu, ukugwema ukuvala okuphoqelelwe kanye nokuthola amandla aphezulu.

Ngaphezu kwalokho, lapho iyunithi isiqalile, i-engela yokubekwa kwe-blade ingashintshwa ibe ubuncane, obunganciphisa umthwalo wokuqala wemoto (cishe 1/3 ~ 2/3 yamandla akalwe); Ngaphambi kokuvalwa phansi, i-angle engela le-blade ingashintshwa ibe yinani elincane, elinganciphisa ijubane lokubuyela emuva kanye nevolumu yamanzi yokugeleza kwamanzi ephampu, futhi inciphise ukulimala komthelela wokugeleza kwamanzi emishini.

Ngamafuphi, umphumela wokulungiswa kwe-lemple angle ubalulekile: ① Ukulungisa i-angle ngenani elincane kwenza kube lula ukuqala futhi kuvale phansi; ② Ukulungisa i-angle ngenani elikhudlwana kukhulisa izinga lokugeleza; ③ Ukulungiswa kwe-angle kungenza iyunithi yepompo iqhube ngezomnotho. Kungabonakala ukuthi i-blade ajudster ithatha isikhundla esibaluleke kakhulu ekusebenzeni nasekuphathweni kweziteshi eziphakathi nendawo nezinkulu.

Umzimba oyinhloko wephampu eguquguqukayo eguquguqukayo ngokugcwele iqukethe izingxenye ezintathu: inhloko yempompo, umlawuli kanye nemoto.

Ⅰ, ikhanda lepompo

Ijubane elithile le-axial elihlanganisiwe lokugeleza elihlanganisiwe pump lingu-400 ~ 1600 (ijubane elijwayelekile le-axial flow pump lingu-700 ~ 1600), (ijubane elijwayelekile lokugeleza okuxubile lingu-400 ~ 800), kanye nekhanda elijwayelekile lingu-0 ~ 30.6m. Ikhanda lempompo ikakhulukazi lakhiwa ngophondo lwamanzi oluhlanganisiwe (ukuhlanganiswa kwamanzi okuhlangene), izingxenye ze-rotor, izingxenye zomzimba we-impoller, izingxenye zomhlahlandlela, izihlalo zepompo, isingeniso, isingeniso kwizakhi ezibalulekile:

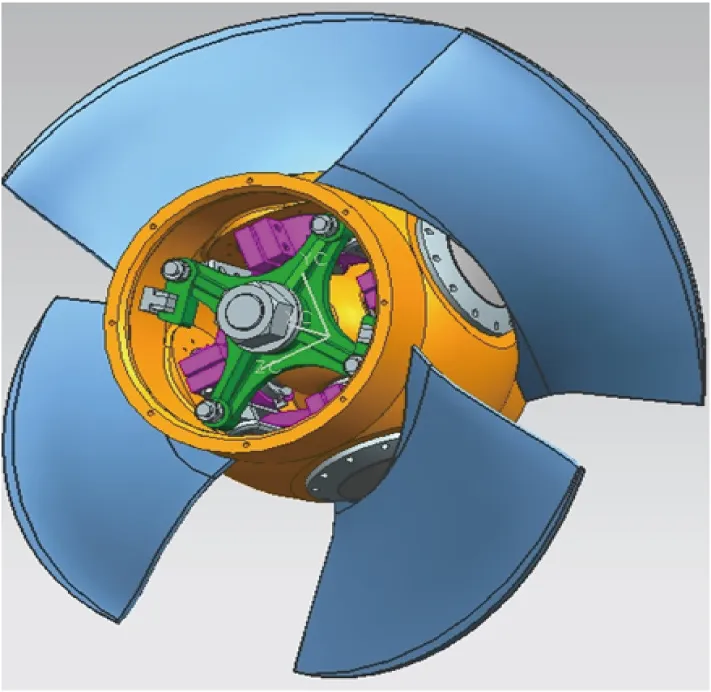

1. Ingxenye ye-rotor yingxenye esemqoka ekhanda lempompo. Siqukethe ama-blade, umzimba we-rotor, induku ephansi yokudonsa, ukuthwala, ingalo ye-crank, uhlaka olusebenzayo, ukuxhuma induku kanye nezinye izingxenye. Ngemuva komhlangano jikelele, kuhlolwa ibhalansi ye-static. Phakathi kwazo, okubonakalayo kwe-blade kungcono kungcono i-ZG0CRCR13NI4MO (Huttness Ovenerness kanye nokuphikiswa okuhle), kanye nemishini ye-CNC yamukelwa. Okuqukethwe kwezingxenye ezisele ngokuvamile kuvame ikakhulukazi i-ZG.

2. Izakhi ze-Impeller Chamber ezivulwa ngokugcwele phakathi, eziqiniswa ngama-bolts futhi zibekwe ngezikhonkwane ezithandekayo. Izinto ezibonakalayo ziyinto ebalulekile ye-ZG, futhi ezinye izingxenye zenziwe nge-ZG + LED STORENLL MET (Lesi sixazululo siyinkimbinkimbi ukukhiqiza futhi sithambekele ekulimaleni kwe-welding, ngakho-ke kufanele kugwenywe ngangokunokwenzeka).

3. Umhlahlandlela Womzimba WaseVane. Njengoba ipompo eguquguqukayo ngokugcwele iyindlela ephakathi nendawo ephakeme yephampu enkulu, ubunzima bokuphonsa, izindleko zokukhiqiza nezinye izici kubhekwa. Ngokuvamile, izinto ezithandwayo yi-ZG + Q235B. Umhlahlandlela uVane uphonswa engxenyeni eyodwa, kanye ne-Shell Flange yipuleti yensimbi ye-Q235B. Bobabili bafakwa futhi bacutshungulwa.

I-4. I-Pump Shaft: Iphampu eguquguqukayo ngokugcwele imvamisa shaft ngenhlamba ye-flange kuyo yomibili imikhawulo. Okuqukethwe okungcono kungcono kwakhiwa ama-45 + ccrriding 30cr13. Ukuqothuka eMhlahlandlela Wamanzi Ukuthwala kanye ne-filler ikakhulukazi ukwandisa ubunzima bayo futhi kuthuthukiswe ukumelana nokugqoka.

Ⅱ. Isingeniso kwizakhi eziphambili zoMlawuli

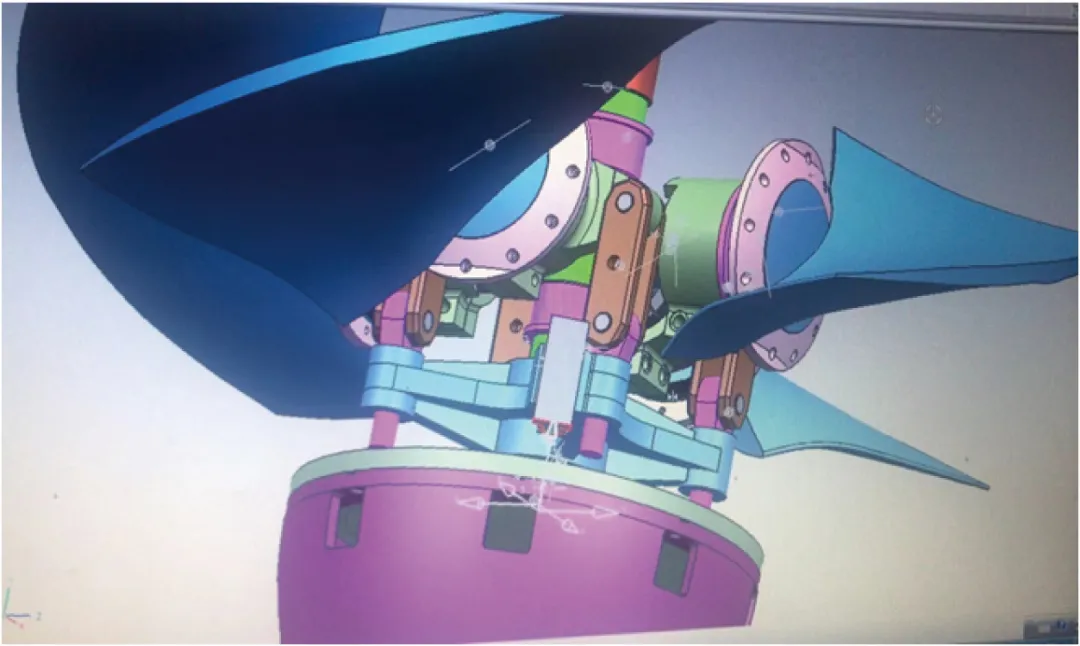

Kulezi zinsuku, i-hydraulic yolawuli ye-hydraulic eyakhelwe ngaphakathi isetshenziswa ikakhulukazi emakethe. Ikakhulu iqukethe izingxenye ezintathu: ukujikeleza umzimba, ikhava, nebhokisi lesistimu yokulawula.

1

Wonke umzimba wokujikeleza ubekwa emgodini wezimoto eziphambili futhi ujikeleze ngokuvumelanisa ne-shaft. Kuboshwe esiqongweni sekhefu elikhulu lezinto eziphambili ngokusebenzisa i-flange ekhuphukayo.

I-Flange ekhuphukayo ixhumeke esihlalweni esisekelayo.

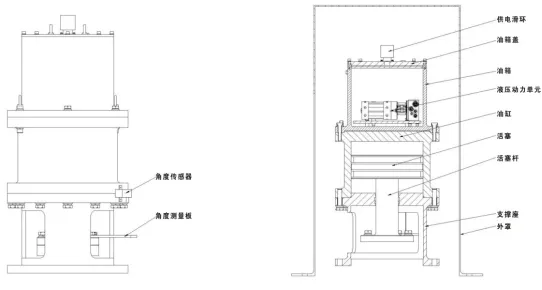

Iphuzu lokulinganisa lensor ye-angle lifakiwe phakathi kwenduku yepiston kanye ne-tie rod sleeve, futhi inzwa ye-angle ifakiwe ngaphandle kwesilinda kaphethiloli.

Indandatho yokuthambisa kwamandla kagesi ifakiwe futhi ilungiswe embozweni samathangi kaphethiloli, kanye nengxenye yayo ejikelezayo (i-rotor) ijikeleza ngokuvumelanisa nomzimba ojikelezayo. Ukuphela kokuphuma ku-rotor kuxhunyiwe kwiyunithi yamandla we-hydraulic, inzwa yokucindezela, inzwa yokushisa, inzwa ye-angle, kanye nokushintsha komkhawulo; Ingxenye yeStator ye-Power Supply Slip Ring ixhunyiwe esikhaleni sokumisa esisembozweni, bese kuthi indawo ethengiwe esitokisini ixhumeke kwisiginali esisembozweni soMlawuli;

Induku yepiston iboshelwe induku yepompo yempompo.

Iyunithi lamandla weHydraulic lingaphakathi kwethangi likaphethiloli, elinikeza amandla isenzo sesilinda kaphethiloli.

Kunezindandatho ezimbili zokuphakamisa ezifakwe ethangini lamafutha ukuze zisetshenziswe lapho uMlawuli ephakanyisiwe.

2. Isembozo (esibizwa nangokuthi umzimba ohleliwe): Siqukethe izingxenye ezintathu. Ingxenye eyodwa isembozo sangaphandle; ingxenye yesibili isembozo sekhava; Ingxenye yesithathu yiwindi lokubheka. Isembozo sangaphandle sihlelwe ngaphezulu kwesembozo sangaphandle semoto esemqoka futhi simboza umzimba ojikelezayo.

I-3. Ibhokisi lokubonisa lesistimu yokulawula (njengoba kukhonjisiwe kuMdwebo 3): Iqukethe i-PLC, isikrini sokuthinta, ukudluliselwa, ukutholwa kwamandla, isikrini sokuthinta singakhombisa i-angle yamanje, isikhathi, ukucindezela uwoyela kanye namanye amapharamitha. Uhlelo lokulawula lunemisebenzi emibili: Ukulawulwa kwendawo nokulawula okukude. Lezi zindlela ezimbili zokulawula zicishwa nge-knob yesikhundla ezimbili kwibhokisi lesistimu yokulawula (okukhulunywa ngalo ngokuthi "ibhokisi lokulawula lokulawula", okufanayo ngezansi).

3. Ukuqhathanisa nokukhethwa kwama-motor avumelanayo nawokuvumelanisa ama-asynchronous

A. Izinzuzo nokubi kwama-motor avumelanayo

Izinzuzo:

1. Igebe lomoya eliphakathi kwe-rotor kanye nesitebhisi likhulu, futhi ukufakwa nokulungiswa kwendlela elula.

2. Ukusebenza okubushelelezi kanye namandla aqine ngokweqile.

3. Ijubane aliguquki ngomthwalo.

4. Ukusebenza okuphezulu.

I-5. I-Power Factor ingathuthuka. Amandla asebenzayo anganikezwa kwigridi yamandla, ngaleyo ndlela athuthukise ikhwalithi yegridi yamandla. Ngaphezu kwalokho, lapho isici samandla siguqulwa ku-1 noma eduze kwaso, ukufundwa ku-ammeter kuzokwehla ngoba isakhi esisebenzayo kwalawo samanje sincishisiwe, okungenakwenzeka kuma-motor ase-asynchronous.

Okubi:

1. I-rotor idinga ukunikezwa amandla yithuluzi lokuhambisa elizinikezele.

2. Izindleko ziphakeme.

3. Isondlo siyinkimbinkimbi ngokwengeziwe.

B. Izinzuzo nokubi kwama-motor ase-Asynchronous

Izinzuzo:

1. I-rotor ayidingi ukuxhunywa kweminye imithombo yamandla.

2. Isakhiwo esilula, isisindo esikhanyayo, nezindleko eziphansi.

3. Ukulungiswa okulula.

Okubi:

1. Amandla asebenzayo kumele adonswe kwigridi yamandla, ewohloka ikhwalithi yegridi yamandla.

2

C. Ukukhethwa kwama-motors

Ukukhethwa kwama-motors anamandla alinganiselwe we-1000kW kanye nejubane elilinganiselwe le-300r / min kufanele kunqunywe ngokusekelwe ekuqhathaniseni kwezobuchwepheshe nakwezomnotho ngokuya ngezimo ezithile ngokuya ngezimo ezithile.

1. Embonini wamanzi osondela, lapho umthamo ofakiwe ungaphansi kwama-800kw, kukhethwa ama-asynchronous motors. Lapho umthamo ofakiwe mkhulu kune-800kw, kukhethwa ama-motors avumelanayo.

2. Umehluko omkhulu phakathi kwama-motor avumelanayo nama-asynchronous motors ukuthi kukhona ukuthokozela i-rotor, futhi isikrini sokuxoxisana se-thyristor sidinga ukulungiswa.

I-3. UMnyango Wezwe Wami Amandla Ezwe ubeka ukuthi i-Power Factor ekunikezelweni kwamandla komsebenzisi kumele ifinyelele ngaphezulu kwe-0.90. Ama-motors avumelanayo anesizathu samandla aphezulu futhi angahlangabezana nezidingo zokuhlinzekwa kwamandla; Ngenkathi i-asynchronous motors inesizathu samandla aphansi futhi ayikwazi ukufeza izidingo zokuhlinzekwa kwamandla, futhi isinxephezelo samandla asebenzayo siyadingeka. Ngakho-ke, iziteshi zamaphampu zihlome nge-Asynchronous Motors ngokuvamile zidinga ukufezekiswa ngezikrini zokunxephezelwa kwamandla asebenzayo.

4. Isakhiwo se-Synchronous Motors siyinkimbinkimbi ukwedlula lokho kwe-asynchronous motors. Lapho iphrojekthi yesiteshi sepompo idinga ukubheka amandla kagesi kanye nokushintshashintsha kwezigaba, ama-motors avumelanayo kufanele akhethwe.

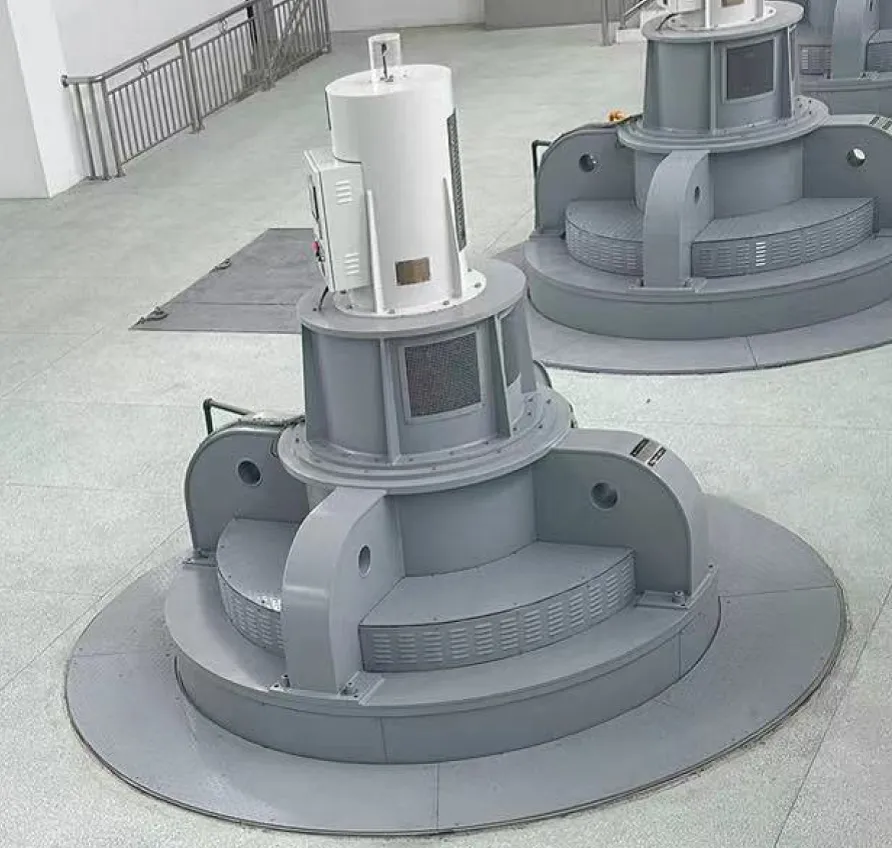

Amaphampu aguquguqukayo aguquguqukayo ngokugcweleIsetshenziswa kabanzi emayunithi abheke mpo (ZLQ, HLQ, Zlqk), avundlile (athambise) amayunithi (ZWQ, ZXQ, ne-ZGQ), futhi angasetshenziswa amayunithi we-LP aphansi kanye nama-LP amakhulu.

Isikhathi Sokuthumela: Oct-18-2024