1. Ngaphambi kokusebenzisa:

1) .Khetha ukuthi ngabe kukhona uwoyela egumbini lamafutha.

2). Bheka ukuthi i-plug neaving gasket egumbini likawoyela ziphelele. Bheka ukuthi ipulaki liye laqinisa i-gasket yokubopha uphawu.

3) .Beka ukuthi umsizi ujikeleza ngezindinganiso.

4). Bheka ukuthi ngabe idivaysi yokuhlinzeka kwamandla iphephile, ithembekile futhi ijwayelekile, hlola ukuthi ucingo oluyisisekelo kukhebula lusekelwe khona, nokuthi iKhabinethi elawula likagesi liye lasuselwa yini.

5) Ngaphambi kokubafuthaUfakwa echibini, kufanele ifakwe ukuze uhlole ukuthi ngabe indlela yokujikeleza ilungile. Indlela yokujikeleza: ibukwe kusuka ku-pump inlet, ijikeleze ngokuqhekeka okuphikisayo. Uma ukuqondiswa kokujikeleza kungalungile, ukuhlinzekwa kwamandla kufanele kunqunywe ngokushesha futhi noma yiziphi izigaba ezimbili zezintambo zesigaba ezintathu ezixhunywe kuwe, v futhi w kukhabethe yokulawula kagesi kufanele kuthathelwe indawo.

I-6) Qalisa ngokuqinile ukuthi ipompo ikhubazekile noma ilimele ngesikhathi sokuhamba, ukugcinwa nokufakwa, nokuthi ama-fasteners akhululekile noma awe.

7) Uma kutholakala ukuthi kungahle kube nokuvuza kanye nopende ompofu, kufanele kusingathwe kahle ngesikhathi.

8). Sebenzisa i-500V Megohmmeter ukukala ukumelana kokufakelwa phakathi kwezigaba kanye nomhlaba ohlobene nemoto, uma kungenjalo ukuthambekela kwetafula kuzomiswa kulelo moto kungabi ngaphezu kwe-120 c .. noma ukwazisa umenzi ukuthi kusiza.

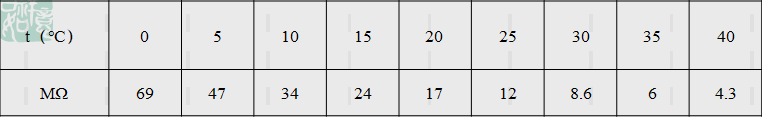

Ubudlelwano phakathi kokumelana nobuncane obubandayo bokulwa nokushisa okubandayo nokushisa okukhona kukhonjisiwe etafuleni elilandelayo:

2. Ukuqala, ukugijima nokumisa

1).Ukuqala nokugijima:

Lapho uqala, vala ukugeleza okulawula i-valve epayipini lokukhipha, bese uvula i-valve kancane ngemuva kokuthi ipompo isebenza ngejubane eligcwele.

Musa ukugijima isikhathi eside nge-calve valve evaliwe. Uma kukhona i-valve ye-inlet, ukuvulwa noma ukuvalwa kwe-valve akunakushintshwa lapho ipompo isebenza.

2).Ima:

Vala ukugeleza okulawula i-valve epayipini lokukhipha, bese uyeka. Lapho amazinga okushisa ephansi, uketshezi ephampu kufanele kukhishwe ukuvikela ukuqanda.

3. Lungisa

1).Hlola njalo ukumelana kokufakelwa phakathi kwezigaba kanye nesiza sezinto ezihlobene nemoto, nenani layo ngeke libe ngaphansi kwenani elibhalwe phansi, uma kungenjalo lizokweqisa, futhi ngasikhathi sinye, libheke ukuthi ngabe kunesisekelo yini.

2).Lapho imvume ephezulu phakathi kwendandatho yokubopha uphawu ifakwe emzimbeni wepompo kanye nentamo yabangemuva endaweni yobubanzi kudlula i-2mm, kufanele kushintshwe indandatho entsha yokubopha.

3).Ngemuva kokuthi iphampu isebenza ngokujwayelekile uhhafu wonyaka ngaphansi kwezimo ezisetshenziswayo ezisetshenziswayo, hlola isimo segumbi lamafutha. Uma uwoyela egumbini likawoyela e-emulsow, buyisela uwoyela we-N10 noma uN15 Mechanic ngesikhathi. Amafutha egumbini likawoyela angezwa ku-filler kawoyela ukuze achichime. Uma uphenyo lokuvuza lwamanzi lunikeza i-alamu ngemuva kokugijima isikhashana ngemuva kokushintshwa kwamafutha, uphawu lwemishini kufanele lusetshenziswe ngokweqile, futhi uma lulimele, kufanele luncweliswe. Okwamaphampu asetshenziswa ezimweni zokusebenza ezinzima, kufanele athembeke njalo.

Isikhathi Seposi: Jan-29-2024