Ekukhetheni amaphampu wamanzi, uma ukukhethwa kungafanele, izindleko zingaba phezulu noma ukusebenza kwangempela kwephampu kungenzeka kungahlangabezani nezidingo zendawo. Manje nikeza isibonelo ukukhombisa izimiso ezithile ithempula yamanzi ezidinga ukuyilandela.

Ukukhethwa kwephampu yokukhulisa okuphindwe kabili kufanele unake amaphuzu alandelayo:

1. Ijubane:

Ijubane elijwayelekile linqunywa ngokuya ngezidingo ezinikezwe amakhasimende. Ukwehlisa ijubane lephampu efanayo, izinga lokugeleza elihambisanayo nokuphakamisa kuzokwehla. Lapho ukhetha imodeli, kuyadingeka ukuthi ungacabangi kuphela ukusebenza kwezomnotho, kodwa futhi nezimo zesayithi, ezinjengokuthi: Ukuvunyelwa kokuphikiswa okuphakathi, ukugqoka, amandla okuzikhandla, njll.

2. Ukunqunywa kwe-NPSH:

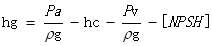

I-NPSH inganqunywa ngokuya ngenani elinikezwe yikhasimende, noma ngokuya ngemibandela yokungenayo yephampu, izinga lokushisa eliphakathi nendawo nokucindezela komkhathi osemkhathini:

Ukubalwa kokuphakama kokufakwa kwephampu yamanzi (i-algorithm elula: ngokuya ngengcindezi ejwayelekile yezulu kanye namanzi okushisa ajwayelekile) kungokulandelayo:

Phakathi kwazo: Ukuphakama kokufakwa kwe-HG-Geometric (inani elifanelekile, inani elingelona iqiniso ligeleza emuva);

Ikhanda lamanzi le -ataspheric elisendaweni yokufaka (libalwa njenge-10.33m ngaphansi kwengcindezi ejwayelekile yasemkhathini kanye namanzi acwebile);

Ukulahleka kwe-HC-Suction Hydraulic; (Uma ipayipi elingenayo lifushane futhi lilula, livame ukubalwa njenge-0.5m)

-Vivalization Pressure Head; (Amanzi acwebile ekushiseni kwegumbi kubalwa njengo-0.24m)

- I-NPSH evunyelwe; (Ukuqinisekisa ukuphepha, ukubala ngokuya nge-NPSHR × 1.2, NPSHR BHEKA ikhathalogu)

Isibonelo, i-NPSH NPSHR = 4M: Ngemuva kwalokho: hg = 10.33-0.5-0.24- (4 × 1.24- (4 × 1.2 (4 × 1.2,2 (4 × 1.2 (4 × 1.2 (4 × 1.2 (4 × 1.2) Yiba mkhulu kunenani elibaliwe, okungukuthi, izinga lokungena kwamanzi lingaba ngaphezulu kwenani elibaliwe ngaphezulu komugqa wesikhungo).

Okungenhla kubalwa ngaphansi kwesimo sokushisa okujwayelekile, amanzi acwebile nokuphakama okuvamile. Uma izinga lokushisa, ubukhulu kanye nokuphakama kwe-medium akujwayelekile, ukuze kugwenywe ezinye izinkinga nezinye izinkinga ezithinta ukusebenza okujwayelekile kwesethi yepompo, amanani ahambisanayo kufanele akhethwe bese efakwa endaweni efomula yokubala. Phakathi kwazo, izinga lokushisa nobuningi bamaphakathi kubalwa ngokuya ngamanani ahambisanayo "ekucindezelweni kwama-vaporization kanye nokuqina kwamanzi emazingeni ahlukene" wokuphakama kwamandla ahambisanayo emadolobheni amakhulu ezweni ". Okunye okuvumelekile kwe-NPSH ukuqinisekisa ukuphepha, ngokusho kwe-NPSHR × 1.4 (Leli nani okungenani lingu-1.4).

3. Lapho ingcindezi ye-inlet yephampu evamile ingu-≤0.2MPA, lapho ingcindezi ye-inlet + inhloko

Ingcindezi ye-Inlet + inhloko Uma ingcindezi ye-inlet iphezulu kakhulu noma ingcindezi yokuhlola iphakeme kakhulu, njll. Lokho akuhlangabezani nezidingo, sicela uqinisekise nobuchwepheshe ukuze bususe impahla noma balungise inqwaba yokwakha udonga;

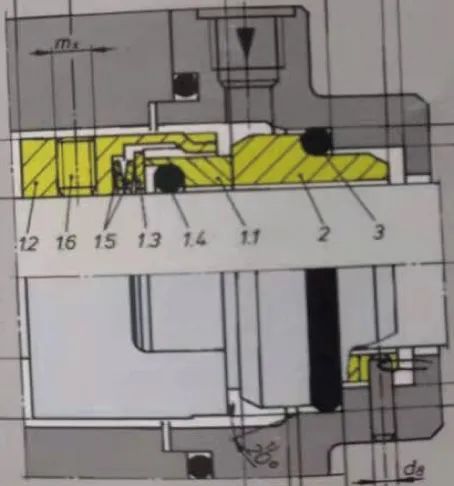

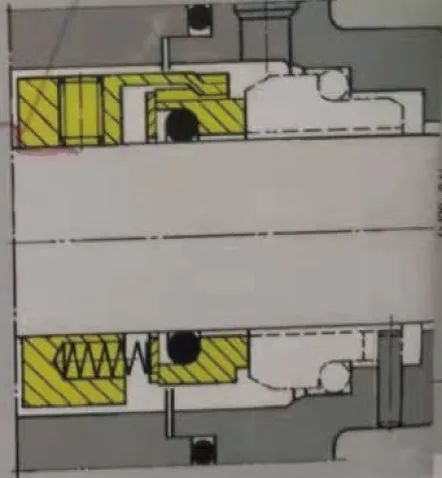

Amamodeli we-4.Convendal Pump Mechanical Seal amamodeli: M7N, M74G-G92 uchungechunge, iyiphi okufanele uyisebenzise kuncike ekwakhiweni kwamaphampu, impahla evamile ye-mechanic seal: Hard / Soft. Lapho ingcindezi ye-Inlet ingu-≥0.8MPA, kukhethwe uphawu olulinganiselwe lwemishini;

I-5. Kunconywa ukuthi izinga lokushisa eliphakathi kwepompoumboni elikhule kabili akufanele lidlule ku-120 ° C. Lapho u-100 ° C Onke ama-O-ring ephampu enziwe ngokusetshenziswa kokubili: I-Fluorine Rubber (kufaka phakathi i-Machineal Seal).

Isikhathi Sokuposa: Meyi-10-2023