I-Abstract: Leli phepha lingenisa iyunithi yepompo ye-Diesel Enjini Esebenzisa ukugeleza kwegesi esebenzisa ukugeleza kwegesi kusuka ku-vacuum, i-veffler tube, njll. I-Putch, njll. I-muffler ixhumeke ngotshani bokufaka wepompo ye-centrifugal, futhi i-value valve ifakwa ethekwini eliphumayo lesikhala senjini yedizili; Kuhlelwa umbhobho wokuphelelwa amandla ngakwesokunene ngasohlangothini lwe-muffler, futhi ipayipi eliphumayo lixhumeke endaweni yokungena komoya ye-Venturi Pipe ye-venturi, futhi ipayipi le-ventuum kanye nepayipi le-vacuum lixhunyiwe ethekwini le-pumple ye-tube. Igesi yokuphelelwa amandla ikhishwe enjini yedizili ikhishwe kwi-Venturi Tube, kanye negesi egunjini lepompo yephampu ye-centrifugal kanye nepayipi lamanzi eliphansi kwe-centrifugal pump elonakele eCentrifugal lingena egunjini lamaphampu ukuze liqashelwe i-Pump Chamber.

I-Diesel Injini Pump Unit uphiko lwamaphampu okunikezela ngamanzi anikwa yinjini yedizili, esetshenziswa kabanzi ematsheni, ukunisela kwezolimo, ukuvikela umlilo nokudluliswa kwamanzi kwesikhashana. Amaphampu wenjini ye-Diesel ajwayele ukusetshenziswa ezimweni lapho amanzi adonswa khona kusuka ngaphansi kokungena kwamanzi okufakwa kwamanzi. Njengamanje, izindlela ezilandelayo zivame ukusetshenziselwa ukumpompela amanzi kulesi simo:

01, faka i-valve engezansi ekugcineni kwepayipi le-inlet yepompo yamanzi echibini lokumunca: ngaphambi kokuqalwa kwepampu ye-diesel injini kuqaliwe, gcwalisa umgodi wamapompo wamanzi ngamanzi. Ngemuva komoya egumbini lepompo kanye nepayipi elingena kwamanzi lepompo lamanzi liyakhishwa, qala iphampu yenjini yedizili isethwe ukufezekisa amanzi ajwayelekile. Njengoba i-valve engezansi ifakwa ezansi kwechibi, uma i-valve engezansi yehluleka, ukulungiswa kunzima kakhulu. Ngaphezu kwalokho, ngokusetha kwephampu enkulu ye-Diesel Injini ye-Tielel

I-02, isethi ye-Diesel Injini yePump ifakwe i-Diesel Injini Vacuum Poom Set: Ngokuqala kuqala i-Diesel Injini ye-Vacuum Pup, ngaleyo ndlela ikhipha ipayipi lamanzi, futhi amanzi emthonjeni wamanzi angena ngepayipi lamanzi elingenayo kanye negumbi lokuphampu ngaphansi kwengcindezi yasemkhathini. Ngaphakathi, qala kabusha i-Diesel Injini Pump esethelwe ukuze kufinyelelwe amanzi ajwayelekile. Ipompo ye-vacuum kule ndlela yokutholwa kwamanzi nayo idinga ukuqhutshwa yinjini yedizili, futhi iphampu ye-vacuum idinga ukufakwa ohlukanisayo wamanzi, ngaphandle kokukhulisa indawo yokuhlala yemishini, kodwa futhi yandisa izindleko zemishini.

I-03, iphampu ye-self-Phriming ifaniswe ne-Diesel Injini: Iphampu ye-Self-Priming inokusebenza okuphansi kanye nevolumu enkulu, futhi iphampu yokuzikhandla inokugeleza okuncane nokuphakama okuphansi, okungakwazi ukufeza izidingo zokusebenzisa ezimweni eziningi. Ukuze unciphise izindleko zemishini ye-Diesel Injini yePump Set, yehlisa isikhala esithathwe yi-Pump Set, bese uwasebenzisa ngokugcwele i-Diesel Injini esetshenzisiwe nge-Pipeline ye-Venturine ye-Venturine ye-Venturing Tube exhumekile I-Port of the Centrifugal Pump Pump Chamber, futhi i-vacuum ikhiqizwa egumbini lepompo yephampu ye-centrifugal kanye nepayipi lamanzi eliphansi kwephampu ye-centrifugal, ingena kumapayipi amanzi epompo wamanzi kanye nephampu yephampu ye-centrifugal, ngaleyo ndlela Ukugcwalisa ipayipi lamanzi elingena kwamanzi ephampu ye-centrifugal kanye ne-pampu yephampu ye-centrifugal, bese iqala i-clutch ukuxhuma injini yedizili nge-centrifugal pump ne-centrifugal pump iqala ukubona ukuthi amanzi ajwayelekile.

二: Umgomo osebenzayo we-tube ye-venturi

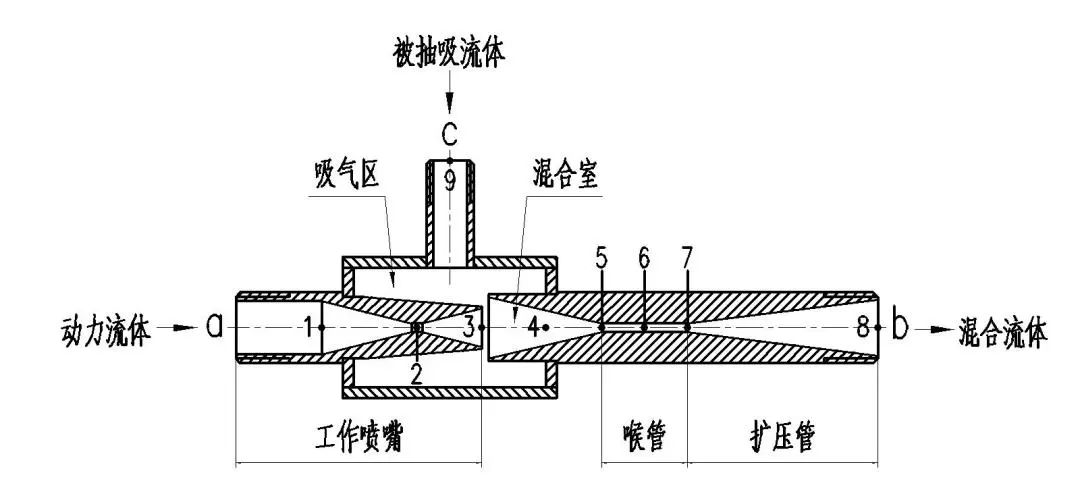

I-Venturi yithuluzi lokuthola i-vacuum elisebenzisa uketshezi lokudlulisa amandla nobunzima. Isakhiwo saso esivamile sikhonjiswa kuMdwebo 1. Kuqukethe i-nozzle esebenzayo, indawo yokumisa, umphimbo wokuxuba, umphimbo kanye ne-diffuser. Kuyinto generator ye-vacuum. Ingxenye esemqoka yedivayisi iyinto entsha, esebenza kahle, ehlanzekile futhi enobuhlakani ye-vacuum esebenzisa umthombo wamanzi omuhle wokukhiqiza ingcindezi engemihle. Inqubo esebenzayo yokuthola i-vacuum inje:

I-01, isigaba esivela ePoint 1 to Point 3 yisigaba sokusheshisa soketshezi olunamandla ku-nozzle. I-fluid ephakeme yengcindezelo yengcindezelo ifaka i-nozzle esebenzayo ye-venturi e-velocity ephansi engxenyeni ye-nozzle inlet (point 1 isigaba). Lapho ugeleza esigabeni se-tapered of the nozzle esisebenzayo (isigaba 1 kuya kwesigaba 2), kungaziwa kusuka ku-fluid mechanics ukuthi, ngokuqhubeka kokugeleza kwengxenye ye-Q2 ye-Q1 yofuba i-Q1 = Q2,

Scilicet A1v1 = A2VV2

Efomula, a1, A2 - indawo yesigaba sendawo yendawo 1 nephuzu 2 (m2);

v1, v2 - I-fluid velocity igeleza ngePoint 1 isigaba kanye nePhoyinti 2 Isigaba, M / s.

Kungabonakala kusuka kwifomula engenhla ukuthi ukukhuphuka kwesigaba sesiphambano, ukugeleza kwe-flow velocity kuyancipha; Ukuncishiswa kwesigaba sesiphambano, ukugeleza kwe-flow velocity.

Kumapayipi avundlile, ngokusho kwe-bernoulli's equation yoketshezi olungaguquki

P1+ (1/2) * ρv12=P2+ (1/2) ρv22

Efomula, P1, P2 - ingcindezi ehambisanayo engxenyeni yesiphambano sephuzu 1 nephuzu 2 (PA)

v1, v2 - velocity (m / s) egeleza esigabeni ngephuzu 1 nephuzu 2

ρ - Ubuningi bukaketshezi (kg / m³)

Kungabonakala kwifomula engenhla yokuthi ukugeleza kwe-velocity ye-flow yoketshezi olunamandla kukhuphuka ngokuqhubekayo futhi ingcindezi iyancipha ngokuqhubekayo kusuka ePhoyinti 1 Isigaba esiseqophelweni esingu-1. Lapho v2> v1, p1> p2, lapho i-v2 inyuka ngenani elithile (ingafinyelela ijubane lomsindo), i-P2 izokwenziwa ngaphansi kwengcindezi eyodwa yomoya, okungukuthi, ingcindezi engemihle izokhiqizwa esigabeni se-point 3.

Lapho uketshezi lwe-tutive lungena engxenyeni yokwanda kwe-nozzle yokusebenza, okungukuthi, isigaba esivela ePhoyinti 2 kuya esigabeni esisesigabeni 3, isivinini soketshezi lwe-motive qhubeka. Lapho uketshezi olunamandla lufinyelela engxenyeni yokuphuma engxenyeni yokusebenza ye-nozzle (isigaba se-point 3), isivinini soketshezi esishukumisayo sifinyelela phezulu futhi singafinyelela isivinini esinamandla. Ngalesi sikhathi, ingcindezi engxenyeni ePoint 3 ifinyelela ubuncane, okungukuthi, i-vacuum degree ifinyelela phezulu, ongafinyelela ku-90kpa.

02., isigaba esivela ePoint 3 ukuze sikhombe u-5 isiteji sokuxuba uketshezi lwe-motive kanye noketshezi olunamapule.

Uketshezi olusheshisa kakhulu olusungulwe yi-fluid enamandla engxenyeni yokuphuma kwe-nozzle (isigaba 3) izokwakha indawo ye-cang egumbini lokuxuba. Uketshezi olugcwele lungeniswe egumbini lokuxuba ePhoyinti lePhoyinti. Ngesikhathi sokugeleza kusuka esigabeni sePhoyinti 9 kuya esigabeni esingu-5, ijubane loketshezi olugcwele lukhuphuka ngokuqhubekayo, futhi ingcindezi iyaqhubeka yehla emandleni engxenyeni engu-13 isigaba esigabeni esingu-13. Ingcindezi yoketshezi engxenyeni yokuphuma kwe-nozzle (point 3).

Esigabeni segumbi lokuxuba kanye nengxenye yangaphambili yomphimbo (isigaba esivela ePoint 3 ukuze sikhombe 6) I-Fluid, ukuze i-velocity yofuba oshukumisayo kancane kancane incipha, ukuvezwa komzimba okumunca kancane kancane, futhi ama-velocities amabili ancipha kancane kancane futhi asondele. Ekugcineni, esigabeni esingu-4, ijubane ezimbili zifinyelela ngejubane elifanayo, futhi umphimbo kanye ne-diffuser ye-venturi ayakhishwa.

三:Ukwakheka kanye nokusebenza komgomo we-Self-Friming Pump Group esebenzisa ukugeleza kwegesi okuphuma kwi-Diesel Injini ukuthola i-vacuum

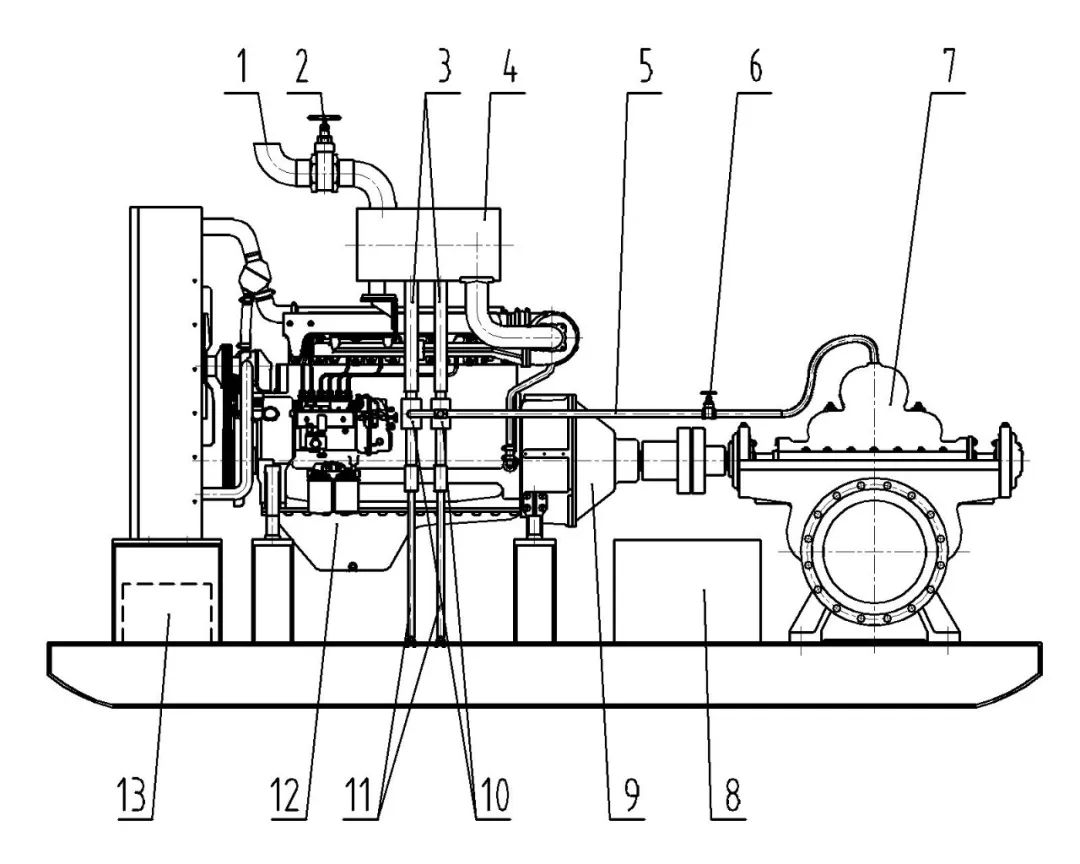

I-Diesel Injini yokukhipha i-effers isho igesi ephumayo ekhishwe yinjini yedizili ngemuva kokuvutha uwoyela wedizili. Kungokwagesi ophelelwe amandla, kepha leli gesi lokuphelelwa amandla linenani elithile lokushisa nengcindezi. Ngemuva kokuhlolwa yiminyango efanelekile yocwaningo, ingcindezi yegesi yokuphelelwa amandla ikhishwe enjini yedizili ifakwe i-turbocharger [3] ingafinyelela ku-0.2MPA. Ngokombono wokusetshenziswa kahle kwamandla, ukuvikela kwemvelo kanye nokuncishiswa kwezindleko zokusebenza, sekuyisihloko sokucwaninga ukuze kusetshenziswe igesi ephelelwe yi-exining ekhishwe ekusebenzeni kwe-Diesel. I-turbocharger [3] Isebenzisa igesi yokuphelelwa amandla ikhishwe ekusebenzeni kwenjini yedizili. Njengengxenye esebenzayo yamandla, isetshenziselwa ukukhulisa ingcindezi yomoya efaka isilinda senjini yedizili, ukuze injini yedizili ingashiswa ngokugcwele, ukuze kuthuthukiswe ukusebenza kwamandla enjini yedizili, kuthuthukise amandla athile futhi kuthuthukise umsindo. Lokhu okulandelayo kuwuhlobo lokusebenzisa igesi ephumayo ekhishwe ekusebenzeni kwe-Diesel Injini njengoketshezi lwamanzi wephakethe le-centrifugal, futhi i-vacuum ikhiqizwa egunjini lamaphampu yePump Centrifugal kanye nepayipi lamanzi le-Centrifugal Pump. Ngaphansi kwesenzo sokucindezela komkhathi, amanzi aphansi kunomthombo wamanzi we-inlet we-centrifugal afaka ipayipi le-inlet yephampu ye-centrifugal, bese egcwalisa ipampu ye-centrifugal kanye ne-pump umgodi ukuze uzuze amanzi ajwayelekile. Isakhiwo saso sikhonjiswa kuMdwebo 2, futhi inqubo yokusebenza imi ngalendlela elandelayo:

Njengoba kukhonjisiwe kuMfanekiso 2, indawo yokungena kwamanzi ye-Centrifugal pump ixhumeke kwipayipi elikhishwe echibini elingaphansi kwepayipi lamanzi, futhi ukuphuma kwamanzi kuxhunywe kwi-valve yamanzi nepayipi. Ngaphambi kokuthi injini yedizili igijime, i-valve yokuphuma kwamanzi wephampu ye-centrifugal ivaliwe, kuvulwe i-valu (6), futhi iphampu ye-centrifugal ihlukaniswe nenjini yedizili nge-clutch. Ngemuva kokuthi injini yedizili iqale futhi isebenza ngokujwayelekile, isango le-valu (2) livaliwe, futhi igesi ephelelwe yi-distel ingena e-veffle piep ngokusebenzisa ipayipi eliphelelwe yisikhathi (4). Kule nqubo, ngokuya ngomgomo we-Venturi Tube, igesi egunjini lepompo ye-centrifugal pump afaka i-venturi tube ngokusebenzisa i-valve valve bese ihlanganiswa nepayipi eliphumayo elivela epayipi lokuqeda. Ngale ndlela, kwakhiwa i-vacuum emgodini wepompo wephampu ye-centrifugal kanye nepayipi lamanzi le-centrifugal pump, namanzi emthonjeni wamanzi aphansi kunephampu ye-centrifugal ipayipi lamanzi ephampu ye-centrifugal ngaphansi kwengcindezi ye-centrifugal ngaphansi kwesenzo se-centrifugal ye-centrifugal pump ye-centrifugal yephampu ye-centrifugal ngaphansi kwengcindezi yasendulo. Lapho i-pampu yephampu ye-centrifugal kanye nepayipi elingena kwamanzi ligcwele amanzi, vala i-valve valve (6), vula i-cangve pump nge-clutch, bese uvula i-valvet ye-valve ye-centrifugal, ukuze ithempeli le-diesel injini liqale ukusebenza ngokujwayelekile. Ukuhlinzekwa kwamanzi. Ngemuva kokuhlola, isethi ye-Diesel Injini yePump ingancela amanzi amamitha amabili ngaphansi kwepayipi lokungena lepompo ye-centrifugal emgodini we-pump we-centrifugal.

Iqembu le-Diesel elishiwo ngenhla le-Diesel Injini ye-Diesel

1. Ngokuphumelelayo Xazulula umthamo wokuzibonakalisa we-Diesel Injini Isethi;

2 Ngakho-ke, isethi ye-Diesel Injini yePumpeli yalesi sakhiwo isindisa isikhala esihlalwe yimishini kanye nezindleko zokufaka, futhi yehlisa izindleko zobunjiniyela.

3. I-Diesel Injini yephampu yesehlakalo yalesi sakhiwo yenza ukusetshenziswa kwephampu yenjini ye-Diesel Injini kusethe xaxa futhi kuthuthukisa uhla lwe-Disel Injini Yezinjini;

I-4. I-tungeru tube kulula ukuyisebenzisa futhi kulula ukuyigcina. Akudingi abasebenzi besikhathi esigcwele ukusiphatha. Njengoba kungekho ngxenye yokuhambisa imishini, umsindo uphansi futhi akukho mafutha wokuthambisa okudinga ukudliwa.

I-5. I-Venturi tube inesakhiwo esilula nempilo yenkonzo ende.

Isizathu esenza ukuthi i-Diesel Injini yePomp Isethi yalesi sakhiwo ingancela amanzi aphansi kunawomanzi e-centrifugal pump, futhi asebenzise ngokugcwele igesi ephumayo ekhishwe ngejubane elikhulu, yenza i-Diesel Injini Pump Set enomsebenzi wokuzibonakalisayo. Ngomsebenzi ozimele.

四: Thuthukisa ukuphakama kokutholwa kwamanzi kwe-Diesel Injini yePump Set

I-Diesel Injini ye-Self-Priming pump sesethi echazwe ngenhla inomsebenzi wokuzikhandla ngokusebenzisa igesi yokuphelelwa yi-expaper ekhishwe ku-Diesel Injini ukugeleza nge-turuum tube ukuthola i-vacuum tube ukuthola i-vacuum. Kodwa-ke, uketshezi lwamandla e-Diesel Injini Pump ebekwe ngalesi sakhiwo yigesi yokuphelelwa yi-Disel ekhishwe yi-Diesel Injini, ngakho-ke, i-vacuum etholwayo nayo iphansi, okukhawulela ubude be-centrifugal pump futhi futhi ibeka imali esetshenziswayo yesethi yepompo. Uma ukuphakama kokumunca kokumunca kwephampu ye-centrifugal kufanele kunyuswe, izinga le-vacuum lendawo yokumunca ye-Venturi tube kumele inyuswe. Ngokusho komgomo osebenzayo we-Venturi Tube, ukwenza ngcono izinga lokwehla kwendawo yokumunca ye-Venturi Tube, i-nozzle yokusebenza ye-Venturi tube kumele yakhelwe. Kungaba uhlobo lwe-sonic nozzle, noma uhlobo lwe-nozzle olungaphezulu, futhi futhi kwandise ukucindezela koqobo koketshezi olunamandla olugeleza nge-venturi.

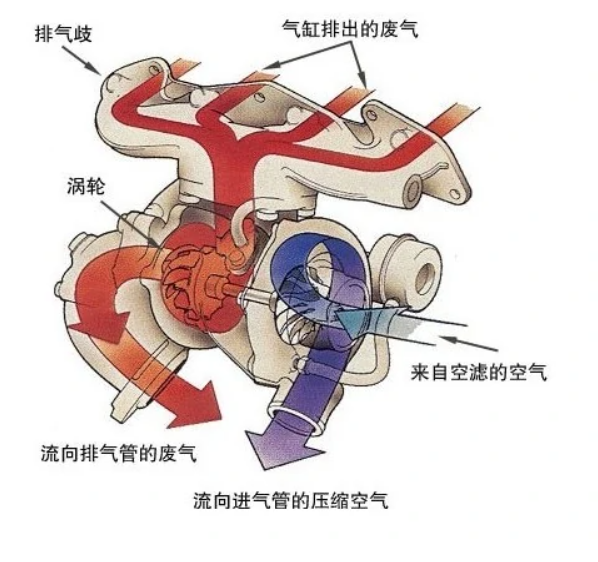

Ukwandisa ingcindezi yokuqala yomanzi we-venturi tutive fluid ogeleza ku-Diesel Injini yePump Set, i-turbocharger ingafakwa epayipi eliphumayo lenjini yedizili [3]. I-turbocharger [3] iyithuluzi lokuncipha komoya, elisebenzisa umfutho we-shop we-gesi okhishwe enjini ukuze acindezele i-turbine egumbini le-turbine, i-turbine idonsa umoya. Ukwakheka kwalo kanye nomgomo wokusebenza kukhonjiswa kuMfanekiso 3.. I-turbocharger ihlukaniswe izinhlobo ezintathu: ingcindezi ephezulu, ingcindezi ephakathi nendawo kanye nengcindezi ephansi. Izingcindezi zegesi ezicindezelwe yilezi: Ingcindezi ephezulu inkulu kune-0.3mpa, ingcindezi ephakathi ingu-0.1-0.3mpa, ukucindezela kwegesi okucindezelwe kungaphansi kwe-turbocharger kuqinile. Uma ukufakwa kwegesi okucindezelwe yi-turbocharger kusetshenziswa njengoketshezi lwamandla we-venturi, kungatholwa isilinganiso esiphakeme se-vacuum, okungukuthi, ukuphakama kokutholwa kwamanzi kwe-Diesel Injini Yezinjini kuyanda.

五: Iziphetho:Iqembu le-Diesel Injini le-Self-Friming Pump esebenzisa ukugeleza kwegesi eliphuma e-Diesel injini ukuthola ukuthi i-vacuum isebenza ngokugcwele injini yokuphelelwa yisikhathi, i-turboCwarging technology ekhiqizwa igesi ye-diesel ukuze ikhiphe igesi ephampu yePump. Kukhiqizwa i-vacuum, futhi amanzi aphansi kunomthombo wamanzi wepompo ye-centrifugal angeniswa epayipi lokungena kwamanzi kanye ne-pow ntactity yephampu ye-centrifugal, ukuze iqembu lepompo ye-Diesel Injini inomphumela wokuzibonakalisa. Isethi ye-Diesel Injini yePumpeli yalesi sakhiwo inezinzuzo zesakhiwo esilula, ukusebenza okulula nezindleko eziphansi, futhi kuthuthukisa uhla lokusetshenziswa kwe-Diesel Injini Yezinjini.

Isikhathi sePosi: Aug-17-2022