Impompo yokuguqula i-Shaft eguqulweyo ngokupheleleyo yi-pump yohlobo oluphakathi kunye nobubanzi obusebenzisa umyinge we-blade osebenzisa i-pump yokuqhuba i-pump yokubekwa, ngokutshintsha i-blade ye-blade yokufumana utshintsho kunye notshintsho lwentloko. Eyona ndawo iphambili yokuhamba ngamanzi ngamanzi acocekileyo okanye ukukhanya okucocekileyo kwi-0 ~ 50 ℃ (amajelo eendaba akhethekileyo aquka amanzi olwandle kunye ne-vallet River). Isetyenziswa ikakhulu kwimimandla yeeprojekthi zolondolozo lwamanzi, ukunkcenkceshela, ukuntywila kunye neeprojekthi zokuphambuka kwamanzi, kwaye zisetyenziswa kwiiprojekthi ezininzi zikazwelonke ezifana neprojekthi yokuphambukiswa kwamanzi e-Huaiihe ukuya kwi-Huaii Hission yeprojekthi yokuphambukisa.

Amabala e-shaft kunye nempompo yokuhamba okuxubileyo agqwethiweyo. Xa iimeko zokusebenza zempompo ziphambuka kwinqaku loyilo, umyinge ophakathi kwesantya esangaphakathi kunye nezangaphandle) kwi-pump yokuhamba-hamba kwimpompo kunye nelahleko yamanzi inyuswe; Ukude kude nendawo yoyilo, enkulu inqanaba lokuphuma kwamanzi kunye nokukhululeka kwamanzi. Iimpompo ze-axial kunye ezixubileyo ezixubileyo zinentloko ephantsi kunye nendawo enomgangatho oncinane. Utshintsho lwentloko yabo yokusebenza luya kubangela ukuncitshiswa okukhulu kwempompo. Ke ngoko, iimpompo ze-axial kunye ne-pumpss ezixutywe ngokubanzi azikwazi ukusebenzisa i-hertling, ijike kunye nezinye iindlela zohlengahlengiso ukutshintsha ukusebenza kweemeko zokusebenza; Kwangelo xesha, kuba iindleko zommiselo wesantya ziphezulu kakhulu, ummiselo wesantya oguquguqukayo unqabile ukuba usetyenziswe ngokomsebenzi. Kuba impompo ye-axial kunye ne-pumps exutyweyo inomzimba omkhulu we-hub, kuyangqinela ukufaka ii-blades kunye neendlela zokudibanisa ii-rod ezinama-engles ehlengahlengisiweyo. Ke ngoko, ukulungelelaniswa kwemeko yokusebenza kweempompo ze-axial kunye nexutywe ngokuxubeneyo kuyakwamkela uhlengahlengiso lwe-angle oluguqukayo, olunokwenza iipompo ze-axial kunye ne-pumps ezixubeneyo zisebenza phantsi kweemeko ezifanelekileyo zomsebenzi.

Xa umahluko wamanqanaba aphezulu anyukayo anyukayo (oko kukuthi, ukunyuka kwentloko yomnatha), i-Angle yeBlade ilungisiwe kwixabiso elincinci. Ngelixa ugcina ukusebenza kakuhle, inqanaba lokuhamba kwamanzi lincitshisiwe ngokufanelekileyo ukunqanda imoto ngokugcwala. Xa i-upstream kunye nenqanaba lamanzi aphezulu ahle kakhulu Ngamafutshane, ukusetyenziswa kweshafti kunye neempompo zokuhamba okuxubeneyo kunokutshintsha i-angle i-blade kunokwenza ukuba isebenze kweyona ndawo ilungileyo, ukunqanda ukuvalwa okuphezulu kunye nokuphumeza ukusebenza okuphezulu kunye nokupeyiphu okuphezulu.

Ukongeza, xa iyunithi iqalile, i-engile yokubekwa kwebala inokulungiswa ubuncinci, enokunciphisa umthwalo wokuqala wemoto (malunga ne-1/3 ~ 2/3 yamandla alinganiselweyo); Ngaphambi kokuba uvale phantsi, umqambi we-blade ungahlengahlengiswa kwixabiso elincinci, elinokunciphisa isantya sesantya sokubuyela umva kunye nomthamo wamanzi wokuhamba kwamanzi kwimpompo yokuvalwa kwamanzi, kwaye unciphise impembelelo yokuhamba kwamanzi kwizixhobo.

Ngamafutshane, isiphumo sohlengahlengiso lwe-bladeng lubalulekile: ① Ukulungelelanisa i-engile kwixabiso elincinci kwenza kube lula ukuqala nokuvala; ② Ukulungelelanisa i-engile kwixabiso elikhulu kunyusa inqanaba lokuhamba; ③ Ukulungelelanisa i-engile kunokwenza iyunithi yempompo ibaleka uqoqosho. Ingabonwa ukuba umyingesi we-Blade Angle uhlala kwindawo ebaluleke kakhulu ekusebenzeni nasekulawuleni izikhululo zempompo eziphakathi nenkulu.

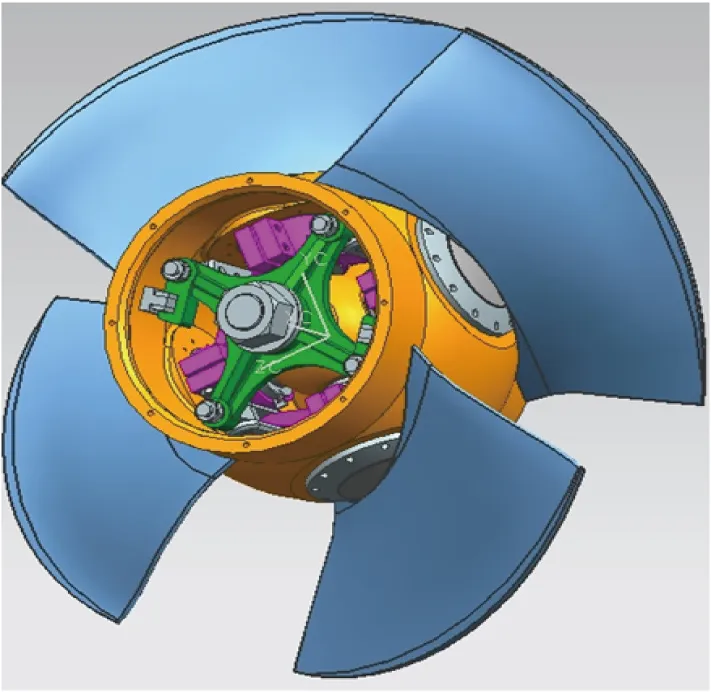

Owona mzimba uphambili wempompo yokuguqulwa kweshaft egxunyeneyo equkethwe iqulethe iinxalenye ezintathu: Intloko yempompo, umlawuli, kunye nemoto.

I-1. Intloko yempompo

Isantya esithile sepompo elungelelanisiweyo ngokupheleleyo yi-400 ~ 1600 (isantya esiqhelekileyo sempompo ye-axial yi-700 ~ 1600), kwaye intloko eqhelekileyo yi-0 ~ 30.6m. Intloko yempompo ibunjwe ikakhulu i-Inlet ye-Inlet yamanzi (indawo yokwandisa amanzi edibeneyo), iinxalenye zeRotor, indawo ye-Imphor, i-Pump, iZitulo ze-Imphul, i-Elbow, indawo yokupakisha, njl. Njl. Intshayelelo yezinto eziphambili:

I-1. Icandelo leRotor yinxalenye engundoqo kwintloko yempompo, edityaniswe ngeBlade, iRotor Mub, iDrown, isakhelo sokusebenza, ukudibanisa intonga kunye namanye amalungu. Emva kwendibano iyonke, uvavanyo lwengozi lwenziwe. Phakathi kwazo, izinto ezibuthathaka kukhetheke kaZg0c13Ni4mo (ubunzima obukhulu nokunganyangeki kakuhle), kunye nomatshini we-CCS ukwamkelwa. Izinto ezisele zenziwe i-Zg.

I-2. Izinto ze-Imphormer Chender zivulwa kakhulu phakathi, eziqiniswe ziibhotile kwaye zibekwe kwizikhonkwane zezonxibelelwano. Isixhobo kukukhetha i-ZG ye-ZG, kwaye ezinye iinxalenye zenziwa ngentsimbi + yentsimbi engenasitali (esi sisombululo siyantywile ekwenzeni nasekuthatheni iziphene, kuya kuthintelwa kangangoko kunokwenzeka).

3. Isikhokelo se-vaner. Kuba impompo eguqulweyo ngokupheleleyo ihamba ngokusisiseko impompo ye-caliber enkulu, ubunzima bokuphosa, iindleko zokwenza imveliso kunye neminye imiba zithathelwa ingqalelo. Ngokubanzi, izinto ezikhethiweyo yi-ZG + Q235B. Isikhokelo i-vane iphoswe kwisiqwengana esinye, kwaye i-shell i-q235b iplate yentsimbi. Ababini bafuduzwa kwaye bagqitywe.

I-4. I-Pump Shaft: Impompo eguqulweyo ngokupheleleyo yi-shaft ye-shaft enezakhiwo zefleni kwiziphelo zombini. Lo mbandela kukhethwa ukuba uqokeleleke ngokukhethekileyo i-45 + ivalinguka i-8ccr13. Ukuvalelwa kwisikhokelo samanzi esithwele kwaye i-filler ingakumbi ukwandisa ubunzima bayo kwaye kuphuculwe ukunyangwa.

二. INTSHAYELELO KWIINGXAKI ZAMABALI

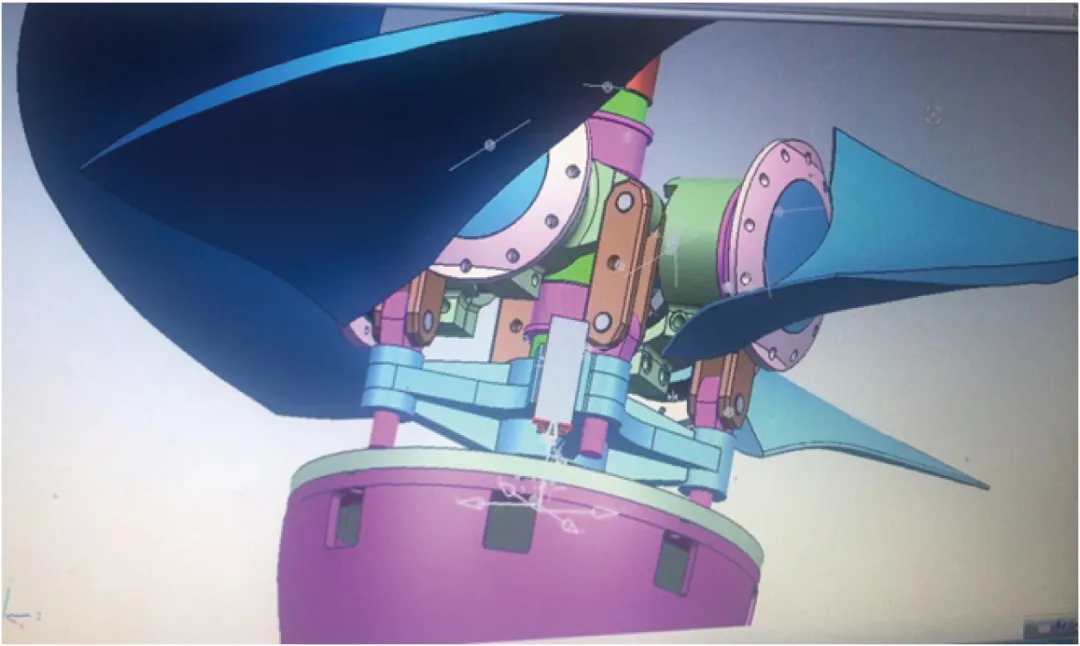

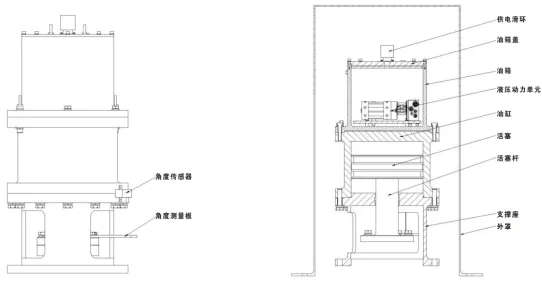

Umlawuli owakhelweyo we-Angle-kwi-Angle-Bladraulic osetyenziswa ikakhulu kwimarike namhlanje. Ibaluleke kakhulu ngamacandelo amathathu: Umzimba ojikelezayo, ikhava, kunye nebhokisi yokubonisa.

I-1. Umzimba ojikelezayo: Umzimba ojikelezayo unesihlalo senkxaso, isilinda, itanki lamafutha, i-hydraulic amandla, i-engle yensor, iringi ye-slip, njl.

Iqumrhu elijikelezayo libekwe kwi-shaft ephambili kwaye ijikeleze ngokuhambelana nomgaqo. Ibilisiwe phezulu kweyona moto iphambili kwi-sunge ye-suping.

IFlange eyonyuke iqhagamshelwe kwisitulo esixhasayo.

Inqaku lokulinganisa lesosi se-Angle lifakwe phakathi kwe-piston rod kunye ne-tie rod ye-tie, kwaye i-angle insor ifakwe ngaphandle kwe-cylinder yeoyile.

Iringi ye-slip yombane ifakiwe kwaye ilungiswe kwikhask yetanki yeoyile, kunye nenxalenye yayo ejikelezayo (i-rotor) ijikeleza ngokudibeneyo ngomzimba ojikelezayo. Isiphelo semveliso kwi-rotor iqhagamshelwe kwiCandelo le-hydraulic, i-Solsor yoTyabo, iSensor yobushushu, iSensor ye-Angle, kunye nokutshintsha umda; Inxalenye ye-stator inxenye yomsesane we-Slip Slip iqhagamshelwe kwisikhafu sokumisa kwikhava, kwaye i-stator yokukhuphela iqhagamshelwe kwi-terminal kwikhava ye-lofisi;

I-piston rod ihonjiswe kwiImpompo yamanzitie rod.

Iyunithi yamandla e-hydraulic ingaphakathi kwitanki yeoyile, ebonelela ngamandla kwisenzo sesilinda yeoyile.

Kukho amakhonkco amabini aphakanyisiweyo afakwe kwitanki yeoyile yokusetyenziswa xa ukuphakamisa uMlawuli.

2. Ikhava (ikwabizwa ngokuba ngumzimba osisigxina): Inamacandelo amathathu. Inxalenye enye sisiciko sangaphandle; Inxalenye yesibini sisigqubuthelo se-Cover; Icandelo lesithathu yifestile yokujonga. Isigqubuthelo sangaphandle sifakiwe kwaye simiselwe ngaphezulu kwesiciko sangaphandle semoto ephambili ukugubungela umzimba ojikelezayo.

3. Ibhokisi yokubonisa yolawulo (njengoko kubonisiwe kumzobo 3): Ine-PlC, iqulethe isikrini se-DC, i-DC, i-DC, i-DC, isambatho soxinzelelo lweoyile kunye nezinye iiparamitha. Inkqubo yokulawula inemisebenzi emibini: ulawulo lwasekhaya kunye nolawulo olukude. Iindlela ezimbini zolawulo zitshintshiwe kwiqhina lesithuba esibini kwiBhokisi yokuDityanisiweyo

三. Thelekisa kunye nokukhethwa kweemotory ze-synchronous

A. Izibonelelo kunye nokungalunganga kweMators Synchronous

Izibonelelo:

I-1. Umsantsa womoya phakathi kwe-rotor kwaye i-stator inkulu, kwaye ufakelo kunye nohlengahlengiso lulungele.

I-2. Ukusebenza ngokutyeba kunye nokulayisha ngaphezulu.

3. Isantya asitshintshi ngomthwalo.

4. Ukusebenza okuphezulu.

I-5. Into enamandla enokukhululeka. Amandla asebenzayo anokubonelelwa kwigridi yamandla, ngaloo nto iphucula umgangatho wegridi yamandla. Ukongeza, xa into etyikitywayo ihlengahlengiswa kwi-1 okanye ikufuphi nayo, ukufunda kwi-Ammeter kuya kuncipha ngenxa yokuncitshiswa kwecandelo elisebenzayo kwi-Motors.

Izinto ezingalunganga:

I-1. I-rotor kufuneka ixhotywe sisixhobo esinikezwe.

2. Ixabiso liphezulu.

I-3. Ukulondolozwa kunzima kakhulu.

B. Izibonelelo kunye nokungalunganga kweemoto ze-asynchronous

Izibonelelo:

1. I-rotor ayifuni kuqhagamshelwa kweminye imithombo yamandla.

2. Ulwakhiwo olulula, ubunzima bokukhanya, kunye neendleko eziphantsi.

3. Ukulungiswa ngokulula.

Izinto ezingalunganga:

1. Amandla asebenzayo kufuneka athathwe kwigridi yamandla, ephakamisa umgangatho wegridi yamandla.

2. Umsantsa womoya phakathi kwe-rotor kunye ne-stator incinci, kwaye ufakelo kunye nohlengahlengiso azisebenzi.

C. Ukukhetha iMotors

Ukukhethwa kweemotor ngamandla aqingqiweyo ye-1000Kw kunye nesantya esiyi-300r / i-min / imiz kufuneka simiselwe ngokusekwe kuthelekiso lobugcisa kunye nezoqoqosho ngokweemeko ezithile.

1. Kwishishini logcino lwamanzi, xa umthamo ofakiweyo uhlala ungaphantsi kwe-800KW, i-Motors Asyshronous ithandwa, kwaye xa umthamo ofakelweyo ungaphezulu kwe-800kw, i-cuwords ehambelana nayo idla ngokukhethwa.

2. Umahluko ophambili phakathi kweMotors kunye neMalinchronous kunye ne-Asynchnous Monts kukuba kukho ubugqwetha kwi-rotor, kwaye i-curistic screen kufuneka ilungiswe.

I-3. ISebe lokubonelela laMandla lam lichaza ukuba izinto zezinto ezenziwa ngamandla yomsebenzisi kufuneka zifike kwi-0.90 okanye ngaphezulu. Imotory ye-Synchronous inezinto eziphezulu zombane kwaye inokuhlangabezana neemfuno zoncedo lwamandla; Ngelixa i-Motors Asynchronous inezinto eziphantsi zombane kwaye azinakuhlangabezana neemfuno zoncedo lwamandla, kwaye imbuyekezo esebenzayo iyafuneka. Ke ngoko, izikhululo zempompo ezixhotywe ngeemoto ze-asynchronous kufuneka zixhotyiswe kwizikrini zembuyekezo.

4. Ulwakhiwo lweemotori ze-synchronous luntsonkothileyo kunezo ze-asynchrous. Xa iprojekthi yesikhululo sempompo kufuneka ithathe zombini iimodyuli zokuvelisa amandla kunye nenqanaba lokuqwalaselwa kwamandla, kufuneka ithathelwe ingqalelo.

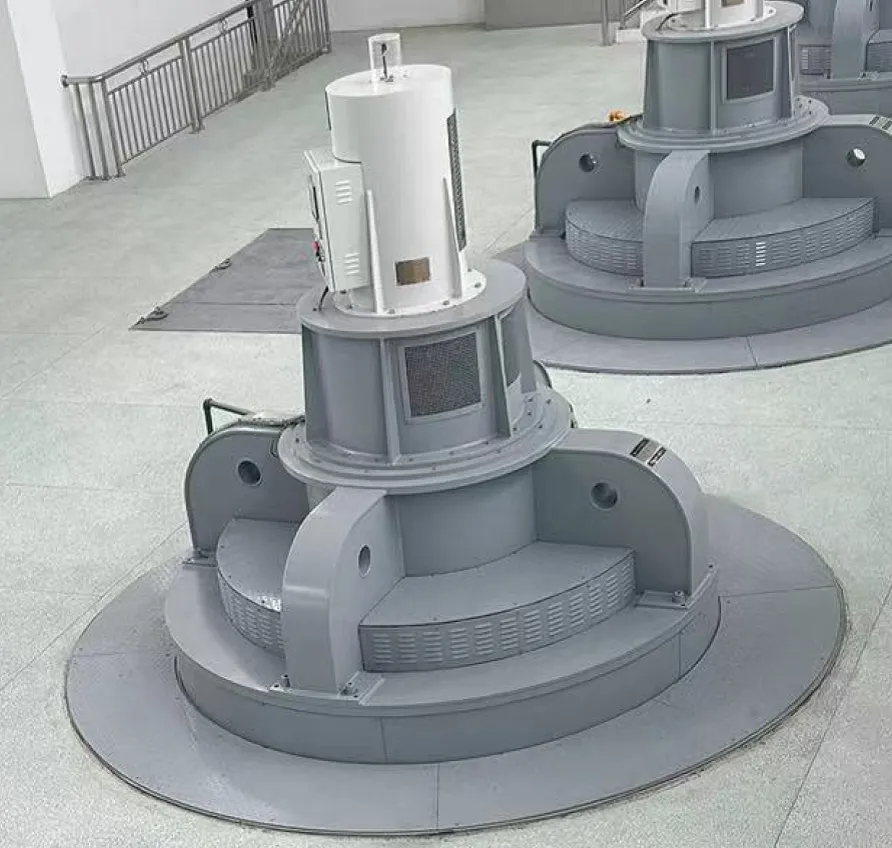

Iimpompo zokuhamba ngokugqibeleleyo ze-axial ezixubileyo zisetyenziswa ngokubanzi ngaphakathiIiyunithi ezithe nkqo(ZLQ, HLQ, Zlqk),Iiyunithi ezithe tye (ezithotyelweyo).

I-Post Time: Aug-30 ukuya kwi-2024