1. Ngaphambi kokusetyenziswa:

1) .Check nokuba ikhona ioyile kwigumbi leoyile.

2). Jonga ukuba iplagi kunye ne-gasket ye-gall yegumbi leoyile zigqityiwe. Jonga ukuba iplagi iqinile i-gasket yokutywina.

I-3)

4). Jonga ukuba ingaba isixhobo sonyulo sombane sikhuselekile, sinokuthenjwa kwaye siqhelekile, jonga ukuba ucingo lomhlaba kwintambo lubekwe ngokuthembekileyo, kwaye nokuba iKhabhinethi yoMoya ixhomekeke ngokuthembekileyo.

5) .Benzele iimpompoifakwe echibini, kufuneka ifakwe ukuba ihlolwe ukuba ingaba indlela yokujikeleza ichanekile. Isikhokelo sokujikeleza: kujongwa kwi-interlet inlet, ijikeleza i-adgallock. Ukuba indlela yokujikeleza ayichanekanga, ukuhambisa amandla kufuneka kunqunyulwe kwangoko kwaye naziphi na izigaba ezibini zekati ezintathu zenqanaba elixhunyiwe kuwe, v kunye ne-W kwiKhabhinethi yoMsebenzi woMbane kufuneka itshintshwe.

I-6). Ngokujonga ukuba impompo icinyiwe okanye yonakele ngexesha lokuhamba, ukugcinwa kunye nokufakelwa, nokuba i-fastteriners ikhululekile okanye iwele.

7) .Check ingaba intambo yonakele okanye yaphukile, nokuba itywina le-inlet yentambo likwimeko elungileyo. Ukuba kufunyenwe ukuba kunokubakho ukuvuza kunye netywina elihlwempu, kufuneka liphathwe kakuhle ngexesha.

8) .I-GOGSMMMMMMMMMMMMM UMGANGATHO WOKUHLAZIYWA KOKUKHUSELEKELWA KWAKHONA KWAKHONA NOKUGQIBELA KWEXESHA LOKUXELWA KWEXESHA LOKUXELWA KWE-FOVIT.

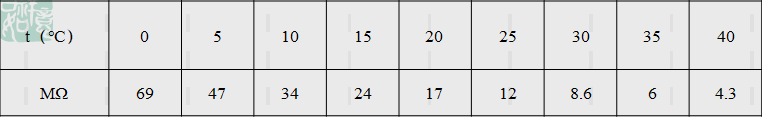

Ubudlelwane phakathi kobuso obubandayo obubandayo kunye nobushushu obubonisiweyo bubonisiwe kule theyibhile ilandelayo:

2. Ukuqala, ukuqhuba kunye nokuma

1).Ukuqala nokusebenza:

Xa uqala, vala ivalve elawula ivalve ekhupha umbhobho, emva koko uvule i-valve ngokuthe ngcembe emva kokuba impompo ibaleka ngesantya esipheleleyo.

Sukubaleka ixesha elide ngevalve ekhutshiweyo. Ukuba kukho ivalve ye-intele, ukuvulwa okanye ukuvala ivalve akunakulungiswa xa impompo iyasebenza.

2).Yeka:

Vala ivalve yokuhambahamba kwi-valiple yokukhupha, emva koko uyeke. Xa iqondo lobushushu liphantsi, ulwelo kwimpompo kufuneka luthathwe ukuthintela ukukhululwa.

3. Ukulungiswa

1).Rhoqo jonga ukunyangwa phakathi kwezigaba kunye nexabiso le-motor, kwaye ixabiso layo aliyi kuba lingaphantsi kunexabiso elidwelisiweyo, kwaye kwangaxeshanye, liphembelelekile.

2).Xa i-coinfornance ephezulu phakathi komkhana wokutywina ofakwe kumzimba wempompo kunye ne-IMPOLLER kwi-SITER kwi-2mm, iringi entsha yokutywina kufuneka itshintshwe.

3).Emva kokuba impompo ibaleka ngesiqingatha sesiqingatha sonyaka phantsi kweemeko ezichaziweyo eziphakathi, jonga imeko yegumbi leoyile. Ukuba ioyile kwigumbi le-oyile inikezelwe, faka i-N10 okanye i-N15 ioyile ngexesha. Ioyile kwigumbi le-oyile yongezwa kwi-oyile yeoyile yokuphuphuma. Ukuba i-probe yokuvuza kwamanzi inika ialam emva kokuqhuba ixesha elincinci emva kotshintsho lweoyile, itywina lomatshini kufuneka lityhafe, kwaye ukuba lonakele, kufuneka lutshintshwe. Ngeempompo ezisetyenziswa kwiimeko zokusebenza ezinobungozi, kufuneka zigxeke rhoqo.

IXESHA LOKUQALA: UJan-29-2024