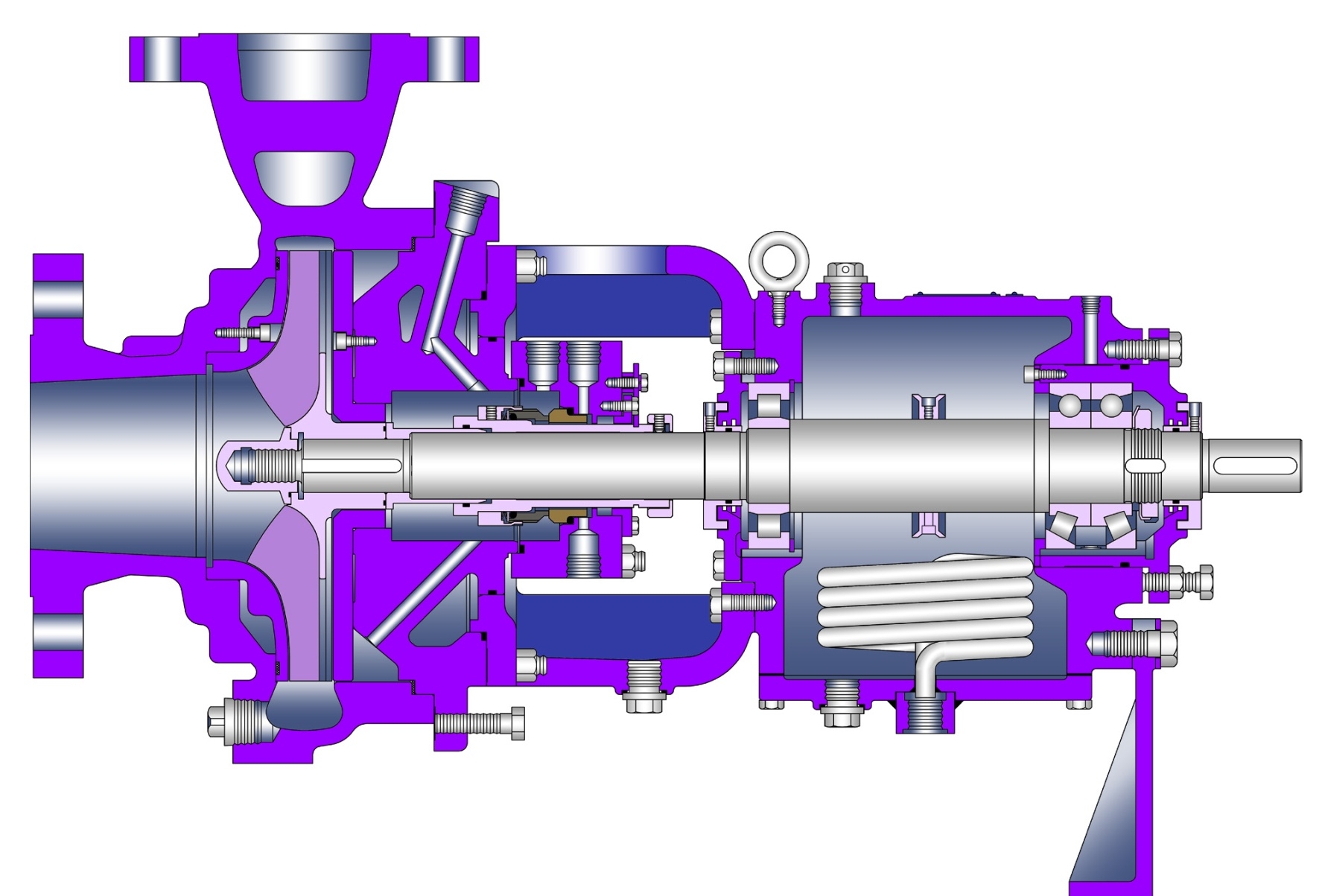

SLZA series are radial split pump casings, among which SLZA is API610 standard OH1 pump, SLZAE and SLZAF are API610 standard OH2 pumps. The degree of generalization is high, and the hydraulic components and bearing components are the same:; series pump types can be equipped with insulation jacket structure; pump efficiency is high; the corrosion allowance of the pump body and impeller is large; the shaft is protected by a shaft sleeve seal, completely isolated from the medium , to avoid the corrosion of the shaft, so that the overall life of the pump is improved; the motor adopts an extended section diaphragm coupling, and the maintenance can be done without dismantling the pipeline and motor, which is very convenient and quick.

pump body

The pump body with a diameter above DN80 adopts double volutes to balance the radial force, thereby reducing the noise of the pump and prolonging the bearing life; the SLZA pump body is supported by the foot, and the SLZAE and SLZAF pump bodies are centrally supported.

Cavitation performance

The blades extend toward the impeller inlet, and the caliber is enlarged at the same time, so the pump has excellent anti-cavitation performance. In special cases, an inducer can be installed to improve the anti-cavitation performance of the pump.

Bearings and Lubrication

The bearing suspension is a whole, the bearing is lubricated by oil bath, and the oil throwing ring ensures sufficient lubrication, so as to prevent local temperature rise caused by low lubricating oil level. According to specific working conditions, the bearing suspension can be non-cooled (with heat dissipation ribs), water-cooled (with water-cooled jacket) and air-cooled (with a fan). The bearings are sealed by labyrinth dust discs.

shaft seal

Shaft seal can choose stuffing or mechanical seal seal. The seal and auxiliary flushing scheme of the pump are configured according to API682 to ensure the seal reliability of the pump under different working conditions.

Application range

Conveying clean and slightly polluted, low and high temperature, chemically neutral and aggressive media.

Mainly used

● Oil refinery, petrochemical industry, coal processing industry and cryogenic engineering @ general process industries such as chemical industry, paper making, pulp industry, sugar industry

● Waterworks and desalination

● Heating and air conditioning systems Auxiliary systems in power stations

● Environmental Protection Engineering

● Ship and Offshore Engineering

Post time: Mar-22-2023