Structural featuresCharacteristics of structure:

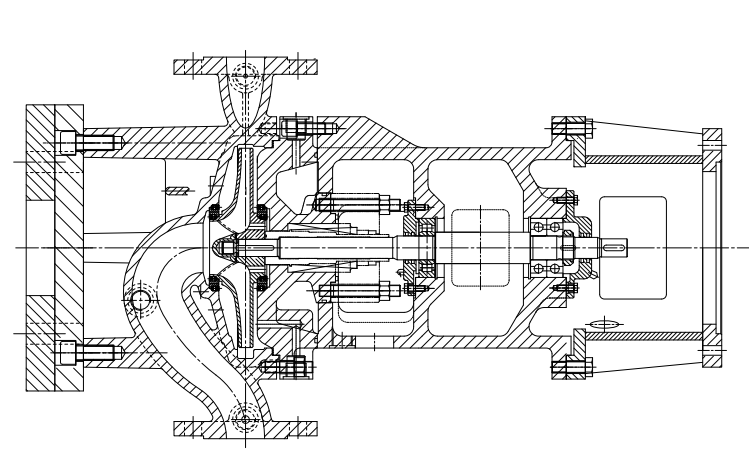

This series of pumps is a single-stage, single-suction, radially split vertical pipeline centrifugal pump. The pump body is radially split, and there is a restricted seal between the pump body and the pump cover. The system with a diameter of 80mm or more adopts a double volute design to reduce the radial force caused by the hydraulic force and reduce the pump pressure. Vibration, there is a residual liquid interface on the pump. The suction and discharge flanges of the pump have connections for measurement and seal flushing.

The inlet and outlet flanges of the pump have the same pressure rating and the same nominal diameter, and the vertical axis is distributed in a straight line. The inlet and outlet flange connection forms and implementation standards can be changed according to the size and pressure level required by the user, and GB, DIN standards and ANSI standards can be used

The pump cover has the functions of heat preservation and cooling, and can be used to send media with special temperature requirements. There is an exhaust plug on the system cover, which can remove the gas in the pump and pipeline before the system starts. The size of the seal chamber meets the needs of packing seal or various mechanical seals. The packing seal chamber and mechanical seal chamber can be used in common, and are equipped with seal cooling. The arrangement of flushing system and seal pipeline circulation system meets the requirements of AP1682 standard

AYG series pumps bear the pump load by rolling bearings, including the load of the pump, the weight of the rotor and the instantaneous load caused by the start of the pump. The bearings are installed in the bearing frame of Yixiu, and the bearings are lubricated by grease.

The impeller of this series of pumps is a single-stage, single-suction, closed-type impeller, which is installed on the shaft by a key and an impeller nut with a wire screw sleeve. The wire screw sleeve has a self-locking function, and the installation of the impeller is complete and reliable; all All impellers are buried in the balance position. When the ratio of the maximum outer diameter of the impeller to the width of the impeller is less than 6, dynamic balance is required; the hydraulic design of the impeller maximizes the cavitation performance of the pump.

The axial force of the pump is balanced by the front and rear grinding rings and balance holes of the impeller. Replaceable pump and impeller wear rings to maintain high hydraulic efficiency of the pump. Low NPSH value, small pump installation height, reduce installation cost.

Scope of application:

Oil refinery, petrochemical industry, general industrial process, coal chemical industry and cryogenic engineering, water supply and water treatment, seawater desalination, pipeline pressurization.

Post time: Mar-07-2023