As we all know, coal coking, also known as high temperature coal retorting, is the earliest applied coal chemical industry. It is a coal conversion process that takes coal as raw material and heats it to about 950 ℃ under the condition of isolating air, produces coke through high temperature dry distillation, and simultaneously obtains coal gas and coal tar and recovers other chemical products. Mainly include cold drum (condensation blast device), desulfurization (HPE desulfurization device), thiamine (spray saturator thiamine device), final cooling (final cold benzene washing device), crude benzene (crude benzene distillation device), steam Ammonia plant, etc. The main use of coke is iron making, and a small amount is used as chemical raw material to manufacture calcium carbide, electrodes, etc. Coal tar is a black viscous oily liquid, which contains important chemical raw materials such as benzene, phenol, naphthalene, and anthracene.

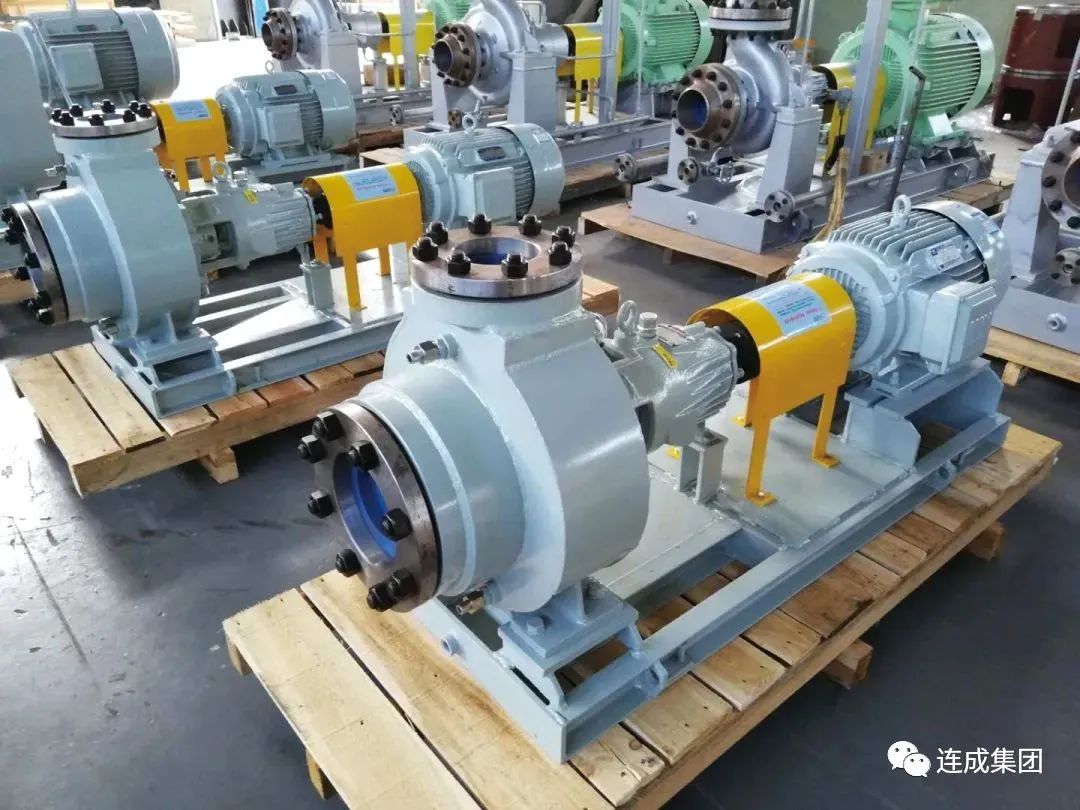

SLZA and SLZAO are the main equipment in coal chemical plant. The SLZAO fully insulated jacket pump is one of the important key equipments for transporting particles and viscous media in the petroleum refining industry and organic chemical industry.

In recent years, Liancheng Group's Dalian factory has successively developed and launched SLZAO and SLZA full-scale products suitable for conveying high temperature, high pressure, flammable, explosive, toxic, solid particles and viscous media such as coal coking through continuous innovation and optimization design. Insulation jacketed pump, and can be equipped with mechanical seal and flushing scheme in accordance with API682.

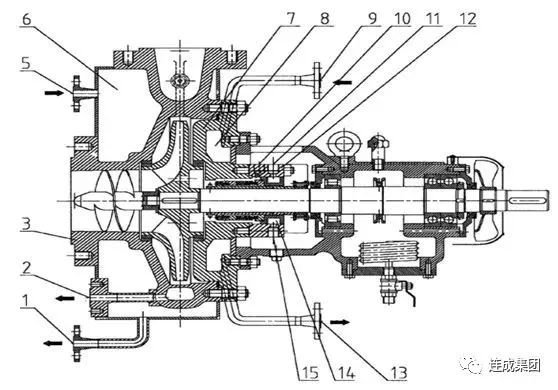

During the development of SLZAO open-type fully insulated jacketed pump and SLZA fully insulated jacketed pump, we cooperated with thermal processing manufacturers, adopted new casting technology, combined with the use of unequal shrinkage casting process design technology, high-strength water-soluble casting materials And low gas generation and anti-sintering casting materials form a new casting process, which solves the problems of pump body pressure, casting welding and wear resistance.

SLZAO open-type fully insulated jacketed pump achieves a technological breakthrough in the product field. The impeller is open or semi-open, with replaceable front and rear wear plates, and has a long service life. The internal surface of the pump adopts a special treatment process to comprehensively strengthen the surface performance of the material, ensuring that the surface hardness of the impeller, pump body, front and rear wear-resistant plates and other overcurrent parts reaches more than 700HV and the thickness of the hardened layer reaches 0.6mm at high temperature (400°C). Coal tar particles (up to 4mm) and catalyst particles are eroded and eroded by the high-speed rotary centrifugal pump, ensuring that the industrial operating life of the pump is greater than 8000h.

The product has a high safety factor, and the pump body is designed with a full thermal insulation structure to achieve the effect of maintaining stable thermal energy. The maximum temperature of the pump is 450℃, and the maximum pressure is 5.0MPa.

At present, the performance has expanded to nearly 100 customers at home and abroad, such as Qian'an Jiujiang Coal Storage and Transportation Co., Ltd., Qinhuangdao Anfeng Iron and Steel Co., Ltd., Qian'an Jiujiang Coal Storage and Transportation Co., Ltd., Yunnan Coal Energy Co., Ltd., Qinhuangdao Anfeng Iron and Steel Co., Ltd., Tangshan Zhongrong Technology Co., Ltd., Chaoyang Black Cat Wuxingqi Carbon Black Co., Ltd., Shanxi Jinfeng Coal Chemical Co., Ltd., Xinchangnan Coking Chemical Co., Ltd., Jilin Jianlong Iron and Steel Co., Ltd., New Taizhengda Coking Co., Ltd., Tangshan Jiahua Coal Chemical Co., Ltd., Jiuquan Haohai Coal Chemical Co., Ltd., etc. have good operating results, low accident rate, fully meet the needs of the process flow, and have been affirmed and praised by customers.

Post time: Mar-31-2022