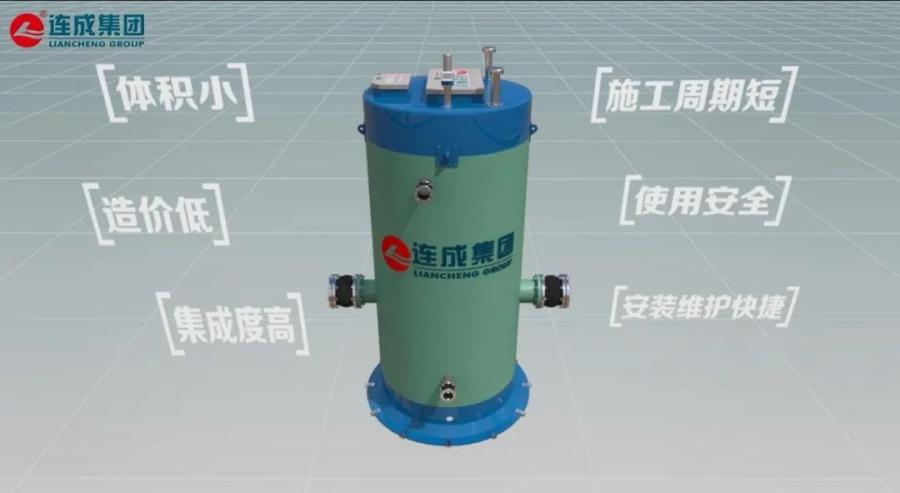

The new integrated smart interception well developed by Shanghai Liancheng (Group) Co., Ltd. effectively solves the problems of difficulty and high cost in the diversion of rainwater and sewage and the transformation of the municipal pipeline network, and realizes the purpose of controlling the source and intercepting the pollution from the source. It is small in size, low in cost, high in integration, short in construction period, safe in use, fast in installation and maintenance, and is an ideal substitute for traditional interception wells. The equipment is widely used in municipal road drainage, rain and sewage diversion transformation, comprehensive treatment of river water bodies, sponge city construction, zero direct sewage discharge, building water supply and drainage and other fields.

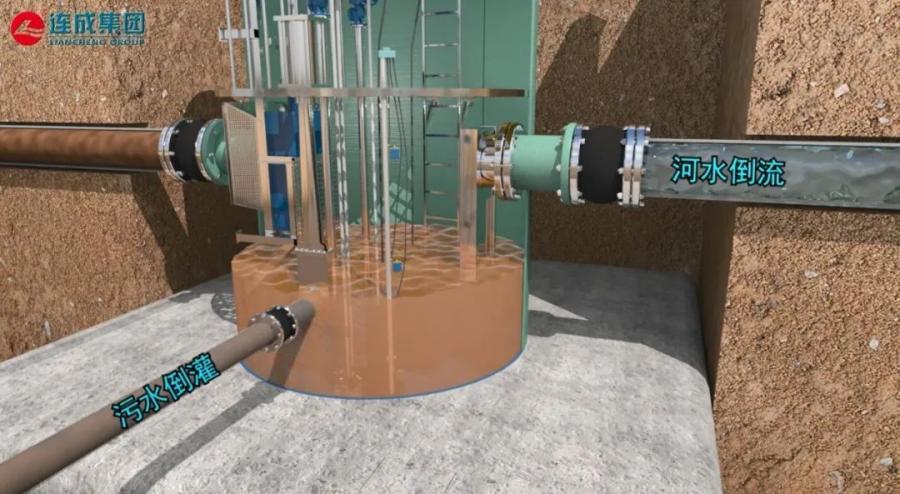

The integrated smart interception well is equipped with a sewage lifting system, a grid system, a liquid level detection system, a rain gauge, a water quality detection system, an smart control diversion system, a remote monitoring system, and an smart cloud monitoring platform. The equipment is monitored by rain gauges, water quality detectors and other instruments for automatic control and remote human control, so as to achieve "all sewage interception in the dry season, early rainwater abandonment, and direct rainwater drainage in the middle and later stages", which can effectively prevent river backflow and sewage backflow. It achieves the purpose of reducing river water pollution, reducing river siltation and reducing the pressure of urban sewage treatment. It is a very effective sewage interception and abandonment facility. It truly achieves zero discharge of sewage and is a major leap in river treatment, source control, and sewage interception technology.

Operating principle:

Sewage interception mode:

On sunny days, the sewage interception gate is open and the rainwater gate is closed. Part of the sewage in the pipeline flows to the sewage pipeline through the sewage interception opening, or is lifted to the sewage pipeline through the sewage lifting device, so that the sewage can be discharged directly on sunny days.

Empty before rain:

According to the weather information, in the early stage of the rainfall, close the sewage interception valve to start the submersible pump, and the power lifts to discharge the sewage to reduce the sewage of the combined pipe network and increase the storage space of the pipe network.

First rain heavy discharge interception and current limiting mode:

When it starts to rain, the rain gauge sends a rain signal. When the polluted initial rainwater enters the interception well, the rain gauge is used to judge the amount of rainfall, or the hydraulic sensor is used to detect the water level in the well, and the interception gate and rainwater gate are opened with a delay to ensure the dirty water. Initial rainwater enters the sewer.

Middle and late rainwater discharge patterns:

After a certain period of continuous rainfall, the water body is gradually clean. At this time, according to the signal of the liquid level sensor and the water quality detector to monitor the water quality compliance signal, it enters the middle and late rainwater mode, the pump stops working, the check valve is automatically closed, and the sewage shut-off valve is closed to prevent sewage from flowing backward , the drainage gates are all opened from top to bottom and the rainwater is directly discharged into the river channel, so as to realize the smooth and rapid discharge of rainwater in the later stage, and alleviate the problem of waterlogging and accumulation of water on urban roads.

The supporting control cabinet of the integrated smart interception well adopts the special control system of Liancheng Company to realize the automatic control of the pumping station. The operation and operation process of the equipment can be programmed with PLC smart control, unmanned management module, GPRS communication interface module, etc., connected to become a smart cloud management platform to realize remote monitoring and unattended operation, which can be accessed at any time on the office computer and mobile phone. Control equipment remotely and understand equipment operation status. In order to supervise the pumping station facilities from a distance, check the operation process or fault prompts at any time, reducing the need for on-site inspection, and when an alarm occurs, the staff can be notified directly through SMS and other methods, making management more convenient and quick!

Post time: Mar-14-2022