ZKY series fully automatic vacuum water diversion device is a new generation of water pump diversion vacuum unit with simple structure, mature application and reasonable configuration based on the summary of our company's many years of production experience and referring to advanced experience at home and abroad. Vacuum water diversion before the start of large mining pumps in water plants, power plants, paper mills, petrochemicals, etc. It completely replaces the traditional structure of installing a bottom valve at the inlet of the suction pipeline when the large-scale water pump is filling, so as to reduce the loss of the suction pipeline and improve the suction performance of the pump.

The ZKY series fully automatic vacuum water diversion device is designed and manufactured for special occasions such as pumping houses, pumping stations (laminar flow pumping stations, etc.), sewage treatment (cyclone wells, etc.) and other vacuum water diversion. This device is used for automatic water filling of water pumps in water pumping stations, so that all water pumps are always in a water-filled state, and any water pump can be started at any time. The device can realize automatic operation of surface pumping station, and can get rid of the traditional semi-underground self-filling automatic pumping station design. Therefore, it can save a lot of pumping station construction costs, avoid the possibility of water pumps being flooded, improve the working environment and operating environment of water pumps, and ensure the safe water supply of water pumping stations. The device has good airtight performance, high degree of automation, easy operation, and work. Safe and reliable.

Background overview:

Traditional steel mill swirl wells, bed cooling pump stations, and iron wall sedimentation tanks generally use vertical long shaft pumps or sealless self-control self-priming pumps. These two solutions have their own shortcomings: 1. The vertical long shaft pump has short service life, high maintenance cost, and the pump efficiency is average (the efficiency value is between 70-80%); 2. The efficiency of the unsealed self-control self-priming pump is low (The efficiency value is 30-50%), the operating cost is large. Therefore, our company designed the SFOW high-efficiency double-suction pump supporting ZKY series full-automatic vacuum water diversion device to replace the long axis pump and self-priming pump.

Advantages of high-efficiency double-suction pump supporting ZKY series vacuum water diversion device:

1. SFOW high-efficiency double-suction pump is a center-open volute centrifugal pump with compact and simple structure, stable performance, easy installation, long service life, convenient maintenance and repair, and low maintenance cost.

2. SFOW high-efficiency double-suction pump adopts advanced hydraulic model, the pump efficiency is high (efficiency value is between 80-91%), and the power consumption of the pump is low at the same working condition (40-50% energy saving compared with self-priming pump, long axis The pump saves nearly 15-30%).

Principle overview:

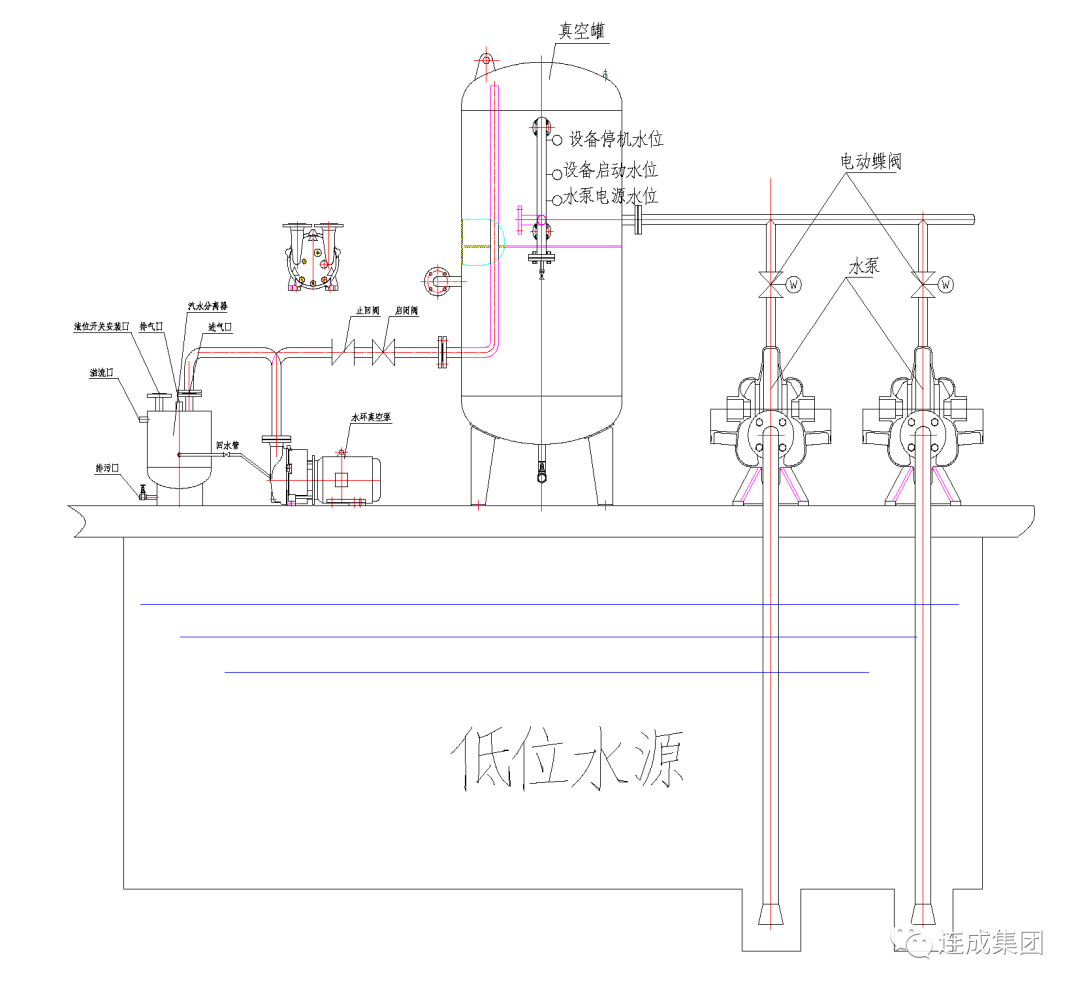

The ZKY vacuum water diversion device is a complete set of vacuum acquisition equipment consisting of SK series water ring vacuum pumps, vacuum tanks, steam-water separators, a set of pipeline valves and a set of electrical automatic control distribution boxes. The vacuum tank is used as vacuum storage equipment. Complete system. The vacuum pump sucks the air in the vacuum tank to form a vacuum in the pump cavity and pipeline connected to it, uses the pressure difference to "induct" the low-level water source into the pump cavity and the vacuum tank, and uses automatic liquid level control equipment to operate to maintain the water level. Let the water level always meet the pump start requirements. When the equipment operates for the first time, the vacuum pump is used to suck the air in the vacuum tank to form a vacuum in the connected system. When the liquid level (or vacuum) drops to the lower limit of the liquid level (or pressure), the vacuum pump starts. When (or vacuum) rises to the upper limit of liquid level (or pressure), the vacuum pump stops. It goes over and over again, using the upper and lower limits of the vacuum pressure to always maintain the vacuum within the working range.

Installation Precautions:

1. The water pump adopts mechanical seal and external flushing water lubrication;

2. When there are multiple pumps, each water pump inlet pipe adopts an independent inlet pipe;

3. There is no need to install any valve in the water inlet pipeline;

4. The water inlet pipeline should not accumulate air (the pipeline should be horizontal and upward, if the diameter is reduced, the eccentric diameter should be used);

5. Pipeline sealing problems (excessive leakage will cause the equipment to start frequently or even fail to stop);

6. The gas path between the equipment and the water pump can only be horizontal or upward, so that the gas can enter the vacuum tank smoothly, so as to ensure that there is no gas accumulation in the pump cavity and pipeline (attention must be paid to on-site installation);

7. The connection position of the equipment and the water pump, looking for the best suction point (to make the water level meet the pump starting requirements), double suction pump, single stage pump, multistage pump (DL, LG), single stage pump, multistage pump can be set Set at the high point of the outlet pipeline, and the double-suction pump is set on the top of the pump volute;

8. The water replenishment interface of the steam-water separator (using the internal water replenishment of the equipment or an external water source).

Equipment composition:

Post time: Aug-19-2020