一. Structure introduction

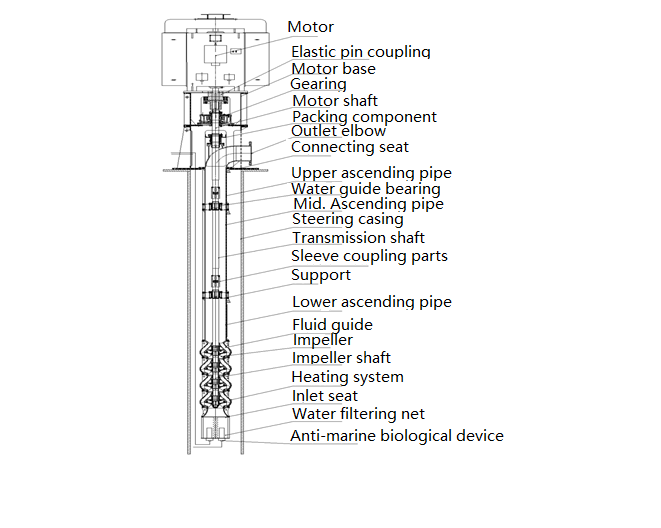

400LP4-200 long axis vertical drainage pump

400LP4-200 long-axis vertical drainage pump is mainly composed of impeller, guide body, water inlet seat, water pipe, shaft, sleeve coupling parts, bracket, bracket bearing, water outlet elbow, connecting seat, motor seat, packing parts , transmission, elastic coupling parts and so on.

1. Rotor parts:

It consists of 4 impellers, 1 impeller shaft, 3 transmission shafts, and 1 motor shaft. The impeller stage sleeve is installed between the impeller and the impeller for axial positioning. The shaft and the shaft are independently designed and manufactured by our company. Rigid couplings——sleeve couplings are used to connect the shafts so that the coaxiality between the shafts is limited to within 0.05mm, so as to ensure the safe and stable operation of the unit. The journal where the filler and the water guide bearing are located is chrome-plated, which makes the journal more wear-resistant and corrosion-resistant, and greatly prolongs the service life of the shaft.

2. Pump body parts:

It consists of 4 diversion bodies, 1 water inlet seat, 1 lower water pipe, 5 middle water pipes, 4 brackets, 1 upward water pipe and 1 water outlet elbow. Between the water pipes, the water pipe and the guide An O-shaped rubber sealing ring is installed between the fluid, the lifting pipe and the water outlet elbow to ensure that the medium will not leak out during the transportation process. The water outlet elbow and diversion body are subjected to a 3.0MPa hydraulic pressure test, which lasts for 5 minutes, and there is no leakage, sweating, etc., to ensure the safe and reliable operation of the unit.

3. Transmission device:

The thrust bearing (SKF bearing in Sweden) is a self-aligning roller and a thrust self-aligning roller bearing, which can well withstand the axial force and radial force generated by the pump during operation. The bearing is lubricated with thin oil, and the shaft seal adopts the combination of skeleton oil seal and felt ring oil seal. A PT100 temperature measuring element is installed near the bearing to ensure that the bearing will not be damaged due to heat during the operation of the pump. The oil tank is equipped with a vibration detector to ensure that the parts or foundation will not be damaged due to excessive vibration during the operation of the pump.

4. Water guide bearing:

The Canadian Sailong bearing (Sailong SXL) is used, which is a combination of high wear resistance and low friction coefficient, and is ideal for water lubrication applications. Compared with rubber bearings, it has many advantages: (1) The stiffness is about 4.7 times that of rubber bearings; (2) It has high impact strength, can absorb impact loads well, and has the toughness to restore its original shape; (3) Corrosion resistance and oil resistance are stronger than rubber; (4) Good dry wear resistance.

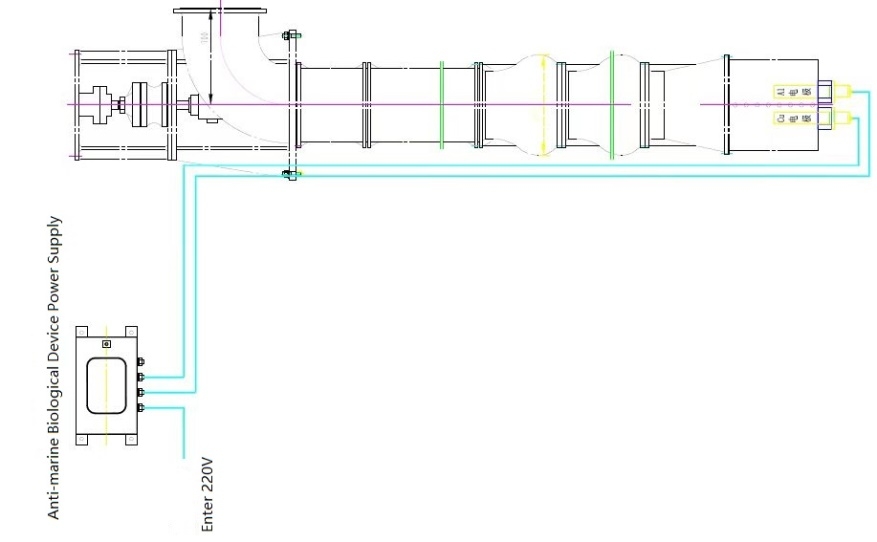

5. Anti-sea biological device:

The principle of the anti-sea organism device system is to reduce the fouling and corrosion of the water pump by electrolysis. The anti-marine power supply applies current to the copper-aluminum electrodes located near the bell mouth of the water pump, generating a large number of ions to form a protective film. This layer of protective film has two functions: one is to prevent the adsorption and growth of marine organisms on the pipe wall, and the other is to prevent seawater from corroding the pump. This system can effectively prevent the growth of marine organisms and kill them (when the ion content in seawater reaches 2 mg per cubic meter, it can effectively prevent the growth of marine organisms).

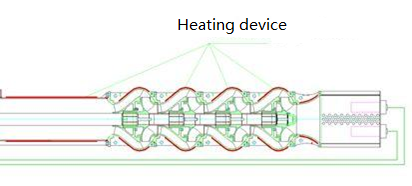

6. Heating device:

Consider that the water in the suction pool freezes in winter and damages the impeller of the pump, the guide body, and the water pipe. Install heating and antifreeze equipment near the impeller of the water pump and the water lift pipe. The start and stop of the device can be automatically controlled according to the water temperature near the water pump impeller to prevent the water near the water pump runner from freezing to damage the water pump impeller, guide body, water pipe and other components.

二. Material introduction of each component of the product

Since the conveyed medium is seawater, the flow part must have strong corrosion resistance. Through communication and discussion with various departments, the final materials of each component are determined as follows:

1. Duplex stainless steel GB/T2100-2017 ZG03Cr22Ni6Mo3N is used for castings such as impeller, guide body, water inlet seat and wear ring;

2. The shaft adopts duplex stainless steel GB/T1220-2007 022Cr23Ni5Mo3N;

3.Pipes and plates are made of duplex stainless steel GB/T4237-2007 022Cr23Ni5Mo3N.

Post time: Feb-03-2023