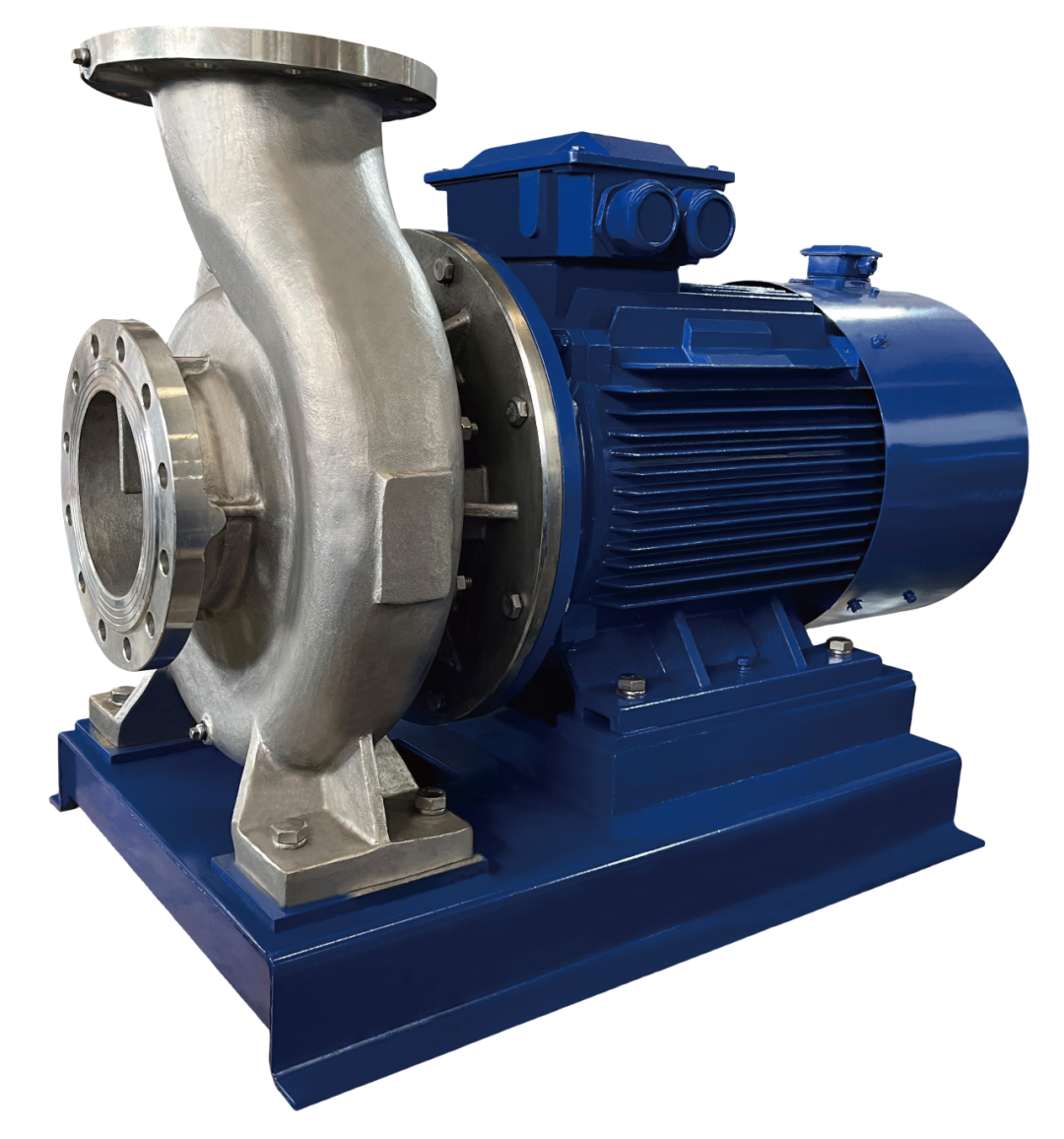

HGL na HGW usoro otu-ogbo naPlay-Founty kwụ ọtọ kemịkaldabere na mgbapụta kemịkal nke ụlọ ọrụ anyị. Anyị na-atụle ihe owuwu ihe eji eme ihe n'oge kemịkalụ n'oge eji eme ihe, sere na ahụmịhe ntọala dị elu n'ụlọ na mba ofesi, ma na-asụpụ nfuli. SCACKES, clamping usoro, nke nwere njiri mara nke ihe owuhe dị mfe, oke oke, obere mkpọtụ, na ndozi dị mma. Ọ bụ ọgbọ ọhụrụ nke otu ọgwụ na-emepụta ihe ọmụmụ.

Akwukwo icho oru

HGL na HGW usoro kemịkalụ kemịkalụEnwere ike iji ya ruo oge ụfọdụ na ụlọ ọrụ kemịkalụ, ihe oriri, ihe ọverageụ, ọgwụ, nchebe gburugburu ebe obibi, nnu na ngwa ndị ọrụ dị ka ọnọdụ ndị ọrụ akọwapụtara. Ọkara nke na-emebi, enweghị ihe ọ bụla siri ike ma ọ bụ obere obere ihe, ma nwee viscosity ụdị mmiri. A naghị atụ aro ya maka iji ihe na-egbu egbu, na-egbu egbu, ihe mgbawa, ma ọ bụ ọnọdụ na-emeri ike.

(1) nitric acid na ngwa na ụlọ ọrụ Nitric acid

Na usoro nke imepụta ammonia oxidip, dilute nitrich acid (50-60%) mepụtara n'ụlọ ebe a na-enweghị eriri na-enweghị mmiri, ma na-ebugharị ya na usoro ọzọ. Lezienụ anya na ọkara okpomọkụ na mgbochi mmiri ebe a.

(2) Ngwa na phosphoric acid na ụlọ ọrụ acid nke phosphoric

Maka acid dị ọcha, nyzọ igwe anaghị agba nchara bụ naanị na-eguzogide ọgwụ nyochara a na-eguzosi ike na steenitic steel na-enweghị ngwọta bụ naanị na-eguzogide ọgwụ nyochara acid. Ihe kachasị mma phosphoric acid na-eguzogide na-eguzogide-nickel-molybrim (zg07cr19ni11mo2 nchara, wdg.

Agbanyeghị, maka usoro mmepụta acid, ihe ihe onwunwe ihe onwunwe nke ihe mgbagwoju anya n'ihi nsogbu corrosion kpatara ọnụnọ nke adịghị ọcha na phosphoric acid, a ga-eji nlezianya mesoo ya.

(3) Ngwa na sodium chloride na ụlọ ọrụ nnu (mmiri brine, mmiri mmiri, wdg)

Chromium-Nickel anaghị agba nchara nwere obere oghere na-acha uhie uhie na ube alkaline na mmiri nnu na ụfọdụ itinye aka na ọnọdụ, ma na-ejikwa ya. Agbanyeghị, ekwesịrị ịchọpụta na corrosonion dị n'etiti ụfọdụ nwere ike iputa oge ụfọdụ.

Nchara nchara ncharaA na-ejikarị ya na ụlọ ọrụ nri maka ijikwa brine na nri salted. Agbanyeghị, a ga-akwụghachi ntị na mgbasa ozi kristal kristal na nsogbu eji egbochi.

(4) Ngwa na sodium hydroxide na ụlọ ọrụ alkali

Chromium-Nickel chronitic anaghị agba nchara ma ọ bụ iguzogide sodium hydroxide dị n'okpuru 40-50% ruo ihe dị ka 80 Celsius C, mana ọ naghị eguzogide na mmiri ịta mmiri alkali dị elu ma dị elu.

Chromium anaghị agba nchara dị mma dị mma maka obere okpomọkụ na obere ngwọta alkali.

A ga-akwụghachi ya na nsogbu nke obere kristal.

(5) Ngwa na ụgbọ njem mmanụ

A ga-akwụghachi anya na viscosity nke ọkara, nhọrọ nke akụkụ roba, na ma moto nwere ihe achọrọ mkpa, wdg.

(6) Ngwa na ụlọ ọrụ ọgwụ

Enwere ike kewaa mgbapụta ahụ ike n'ime ụzọ abụọ ndị a dabere na nnyefe nke mgbapụta:

Otu ụdị bụ nfuli mmiri, pọmpụ mmiri na mmiri na-ekpo ọkụ na-eme na ọrụ ọhaneze, yana ụdị ndị ọzọ bụ nfuli, mmiri dị ọcha, acid na alkalis na alkalis.

Onye nke mbụ nwere obere chọrọ maka nfuli ma a ga-edozi ya site na pọm ji ihe eji eme ihe kemịkal, ebe nke ikpeazụ nwere ihe ndị dị elu maka nfuli. Nfuli ahụ ga-ezute ihe ndị achọrọ maka nfuli Centrifugal eji arụ ọrụ ọgwụ.

(7) Ngwa na nri na ihe oriri na nkwari

Na nri na ụlọ ọrụ ihe ọ beụ, ndị na-adịghị na-abụghị corrosive ma ọ bụ na-esighi ike corrosive, mana anaghị anabata nchara, na ịdị ọcha nke onye na-ajụ a. N'okwu a, enwere ike iji igwe anaghị agba nchara.

Njirimara Nrụpụta

1. Ihe eji emepụta nke ihe mgbapụta nke usoro a pọmịrị na-ezere imebi emebi na-emebir. Nke a na-eme ka ọrụ kwụsiri ike na nke a pụrụ ịdabere na ya.

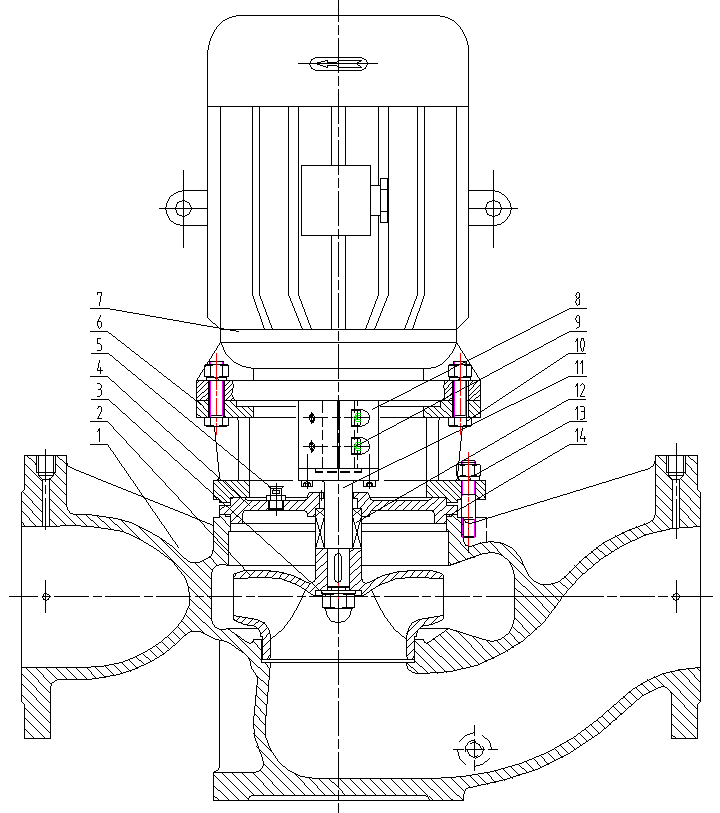

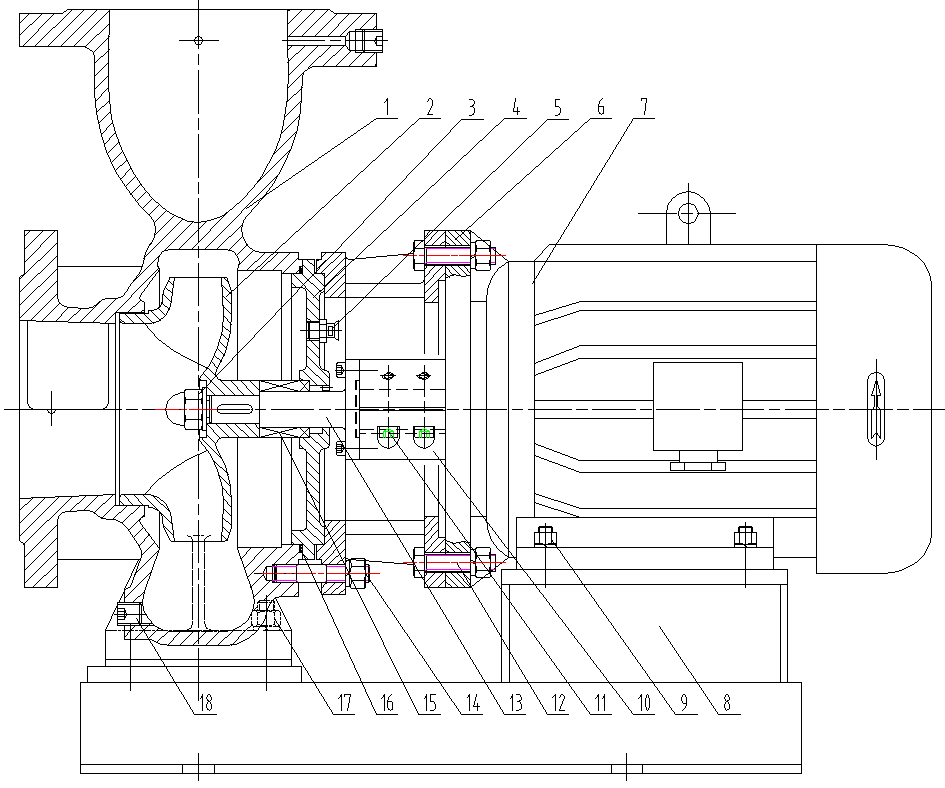

2 Ihe mgbapụta vetikal nwere ike iji ihe eji arụ ọrụ B5 mee ihe n'ụzọ dị mfe iji dogharịa mmiri mgbapụta ahụ, igwe kwụ ọtọ nwere ike iji moto B35 rụọ ọrụ ngwa ngwa iji ụgbọala na-akwọ ụgbọ mmiri.

3

4 Ozugbo ọ dị mkpa ka edochie ya, ọ dị mfe ịgbasa ma wụnye, idobere ya ezi na ntụkwasị obi.

5. Ọkpụkpụ mmiri na-ejikọ ya na usoro nke usoro a na-ejikọ ya site na conglings. Teknụzụ dị elu na ezi uche na teknụzụ na-eme mgbapụta eriri nwere nnukwu ndọtị, enweghị nsogbu na mkpọtụ.

6. TụnyereMkpopụta kemịkalnke izugbe usoro, usoro usoro a kwụ ọtọ nwere usoro kọmpat na oghere ala na-ebelata nke ukwuu.

7. Usoro nke pọmpụ a na-anagide atụmatụ hydraulic. Arụmọrụ nke mgbapụta ahụ kwụsiri ike ma rụọ ọrụ nke ọma.

8. Ahụ mkpuchi ahụ, mkpuchi na akụkụ ndị ọzọ nke usoro ihe ndị ọzọ bụ usoro ziri ezi site na itinye ego na ntinye ego na ọdịdị ndị mara mma.

9. Ihe mkpuchi ahụ, ogwe aka, brackets na akụkụ ndị ọzọ nke usoro pọmpụ na-eme atụmatụ zuru ụwa ọnụ ma na-agbanwe agbanwe.

HGL, HGW Ose Spelent

Oge post: Dec-13-2023